Warehouse Management System Software

Modula WMS Software: Optimized Inventory Management for Maximum Efficiency

Modula’s Warehouse Management System (WMS) software is a powerful tool designed to revolutionize inventory management and streamline operations. Tailored to integrate seamlessly with Modula’s automated storage solutions, the software ensures that businesses can maximize productivity, reduce errors, and maintain full control over their inventory.

What is Modula WMS Software?

Modula WMS is an advanced software platform specifically developed to manage and optimize the performance of automated storage systems such as Vertical Lift Modules (VLMs) and horizontal carousels. It provides real-time inventory tracking, retrieval, and reporting to help businesses maintain efficiency and accuracy in their operations. The software is highly adaptable and can be scaled to suit a variety of industries, including manufacturing, retail, healthcare, and logistics.

How Does Modula WMS Work?

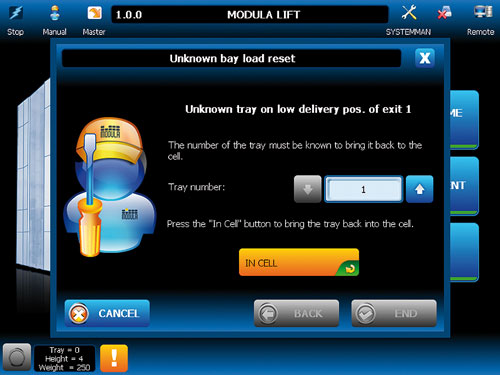

Modula WMS acts as the brain behind your automated storage systems, controlling and coordinating the storage and retrieval of goods. The software organizes inventory into logical categories, tracks item locations, and manages picking and replenishment processes. With its intuitive interface, operators can easily input orders, monitor system performance, and access detailed reports.

Why Choose Modula WMS?

With Modula WMS, businesses gain a robust solution to manage their automated storage systems and achieve peak operational performance. Whether you’re managing complex manufacturing parts, pharmaceutical supplies, or retail inventory, Modula WMS is your partner in driving efficiency, accuracy, and growth.

Experience the difference that Modula WMS software can make for your operations. Contact us today to learn more or request a demo.

Key Features Include:

- Order Management: Simplify and automate the picking process to ensure quick and accurate order fulfillment.

- Inventory Control: Real-time tracking of stock levels and item locations to prevent shortages or overstocking.

- Batch and Wave Picking: Enhance efficiency by grouping multiple orders for simultaneous processing.

- User-Friendly Interface: Simplified dashboards for quick navigation and operation.

- Seamless Integration: One of the standout features of Modula WMS is its ability to integrate effortlessly with existing Enterprise Resource Planning (ERP) systems, Manufacturing Resource Planning (MRP) systems, and other third-party software. This ensures smooth data exchange and alignment between storage operations and broader business processes. Whether it’s SAP, Oracle, Microsoft Dynamics, or other platforms, Modula WMS is designed to fit seamlessly into your workflow.

Benefits of Modula WMS Software:

- Enhanced Efficiency: By automating manual processes, Modula WMS reduces labor requirements and accelerates workflows.

- Improved Accuracy: Minimize picking errors and ensure the right items are always delivered to the right place.

- Space Optimization: Maximize storage density by leveraging advanced inventory organization.

- Scalability: Easily adapt to changing business needs, from small-scale operations to large, multi-facility enterprises.

Base Package

Modula WMS Base is considered an entry level package and is bundled with a Modula purchase; it is suitable for the management of one or more warehouses. This package can manage a maximum of 3 workstations including 1 server.

- Item register management.

- Warehouse location management using a graphical tool.

- Materials handling management through pick/put orders.

- Materials handling management through immediate requests.

- User management with three levels of access.

- Management of physical inventories of the warehouse

- Manual import/export data exchange system with the client’s ERP of fixed format ASCII files.

- Advanced security management with restricted access to specific items and trays based on user’s role

Premium Package

The most complete package for warehouse management. All the functionalities of the BASE package, plus many others.

- Automatic item-compartment allocation and dynamic location management.

- Lot and serial number management.

- Full management with custom tracking of automatic import/export in ASCII, ODBC, Excel and Xml file formats.

- Management of free or tabled sub-codes.

- Material status management.

- Pack type management.

- Expiration date management.

- Advanced user management; configuration of enabled procedures for each individual user.

- Material management by FIFO or by sub-code priority (e.g. picking can be performed giving priority to the lowest and therefore the oldest lot code).

- Justification management for immediate requests.

- STATISTICAL ANALYSIS and CUSTOM REPORTS.

- Full management of warehouse statistics.

- Customization of print reports via print management tool.

- Customization of printed label layout using dedicated tools.

Supplementary Packages for Modula WMS Premium

Advanced Picking: This module provides functionalities to improve picking and replenishing.

- Packing list management.

- Assembly kit management.

- Shipping bay management.

Warehouse management of materials in transit (packages, cartons, boxes). - Automatic creation of storage compartments during replenishing operations.

- Serial number management (management of multiple serial numbers for the same item associated with an individual compartment).

Advanced Item Management: This module extends the functionalities for item management.

- Management of the pre-defined orders that can be replicated as required.

- Association of images to items.

- Grouping items into families to define common characteristics.

- Grouping items into categories for improved search and filtering capabilities.

- Extended fields for item management, orders and order lines via additional attributes.

- Management of alternative article codes.

- Management of borrowed material picking.

Modula Dashboard: The Modula dashboard is a real-time, customizable digital interface that provides an at-a-glance view of your facility’s operations. The user-friendly interface can be accessed from a PC or mobile device and displays order status, item and picking statistics, and more. It is designed to work with the Modula WMS, but can also be configured to integrate data from external sources

Manual Warehouse: This module allows the management of manual areas by software with the following functionalities:

- Management of manual warehouses using an intuitive graphic tool.

- Management of picking activities in manual areas.

- Management of material splitting between different areas based on the quantities handled.

- Management of material reintegration between areas based on user-definable minimum stock levels for different areas.

- Entry area management.

Mobile Picking App: Available for Android devices, The Mobile Picking App is designed to streamline picking and replenishment operations in manual warehouses but can also be used to control Modula Units. Integrating seamlessly with the Modula WMS, the app allows operators to access all necessary information from anywhere in the facility. With its user-friendly interface, the app also includes a built-in barcode reader, enabling operators to scan and track items directly from their mobile device, increasing efficiency by eliminating the need for paper. The Mobile Picking App requires the manual warehouses license

IDOC: Ad-hoc SAP Protocol

This refers to the exchange of data between SAP WMS and Modula WMS (in ASCII format) via IDOC assuming that SAP contains the WM module. The Modula WMS must be seen by SAP as a black box to which the requests and results of the requests are sent via IDOC.

Modula Driver: Does your company already have a WMS? If so, you can choose between Modula Link and Modula Driver to connect to your WMS.

Modula Driver allows high-level warehouse management by way of movement orders (pick, replenish or inventory). These orders are typically sent via an intermediate data base or text file: basically, lists of trays to be moved with the associated picking data.

This system can manage:

- Order preparation bays (with the possible addition of the Put to Light accessory).

- Warehouse historic/statistical data.

Modula Link: Modula Link is a software tool that enables an external Host System to control at low level a group of LIFT OS units using a set of commands managed via communication on a TCP/IP channel socket.

Photo Gallery

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.

Photo Gallery