Dock Design and Planning Guide

Dock Design and Planning Guide

The loading dock is essential to any business. It should operate safely, efficiently, and dependably, as it’s a vital part of prosperity. After all, when a dock is shut down, your business suffers the consequences.

In this comprehensive guide, we delve into the crucial aspects of loading dock planning, offering invaluable insights to tailor your dock design to meet precise requirements for optimal functionality and efficiency. Whether you’re embarking on new construction or considering remodeling/retrofitting, we cover equipment specifications, service plans, and more. With this reference material and the expertise of a local WW Cannon dock specialist, simplifying the process of developing plans for new dock equipment becomes seamless.

- Site Design

The loading dock is typically the busiest spot in your building, with forklifts, pallet jacks, and pedestrians navigating simultaneously. Efficiency is vital for business success. Arrange your dock area logically to avoid congestion and safety risks. Clearly define traffic patterns for operators. Ensure one-way or circular traffic flow, allowing two-way only when aisles are sufficiently wide. A well-designed traffic layout enhances loading/unloading speed and safety.

Efficiency is crucial when choosing optimal dock locations, but safety is equally important. Through proper planning and space management, accidents can be minimized, ensuring unobstructed access for both vehicles and pedestrians.

To initiate the planning process for your facility’s loading docks, assess:

- Truck configurations and daily frequency

- Dimensions of loading docks and doors

- Characteristics of building processes

After evaluating these factors, consider dock height, loading bay width, and the layout of the building interior adjacent to the docks.

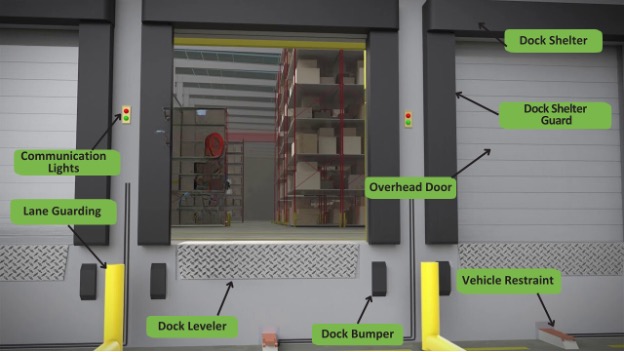

3. Equipment Selection

Dock levelers play a critical role in bridging the gap between the building and semi-trailer during loading and unloading operations. They must effectively adjust to the vertical movement of the trailer and support heavy loads across various trailer types. Consisting of a hinged ramp and lip, dock levelers function similarly by raising the ramp, swinging out the lip, and lowering onto the truck bed once the lip is extended.

The two most common levelers are:

• Recessed dock leveler (pit style) – installed into a pit that is formed in the loading platform

• Edge-of-dock leveler – installed onto the curb face of the loading platform

4. Preventive Maintenance & Service Plans

Preventive maintenance aims to:

- Prevent failure.

- Detect the onset of failure.

- Find hidden failures.

Reactive maintenance, on the other hand, focuses on diagnosing and fixing a problem once an asset has already broken down or malfunctioned. Preventive maintenance emphasizes regularly scheduled maintenance tasks.

WW Cannon offers customized preventative maintenance programs for loading docks and commercial doors to ensure your equipment remains in optimal condition. Scheduled at your convenience, these programs can be arranged annually, semi-annually, quarterly, or even monthly. Each program begins with a complimentary equipment survey, including a thorough inspection of loading dock equipment, vehicle restraints, levelers, and doors. You’ll receive a detailed report outlining the condition and safety level of your equipment, along with recommendations for maintenance or repairs as needed. Partnering with WW Cannon saves you time and money, while fostering a safer and more productive environment in your facility.

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.