How a Reliable Heavy-Duty Vertical Reciprocating Conveyor (VRC) Solved 3 Major Warehouse Challenges in Oklahoma

How a Reliable Heavy-Duty Vertical Reciprocating Conveyor (VRC) Solved 3 Major Warehouse Challenges in Oklahoma

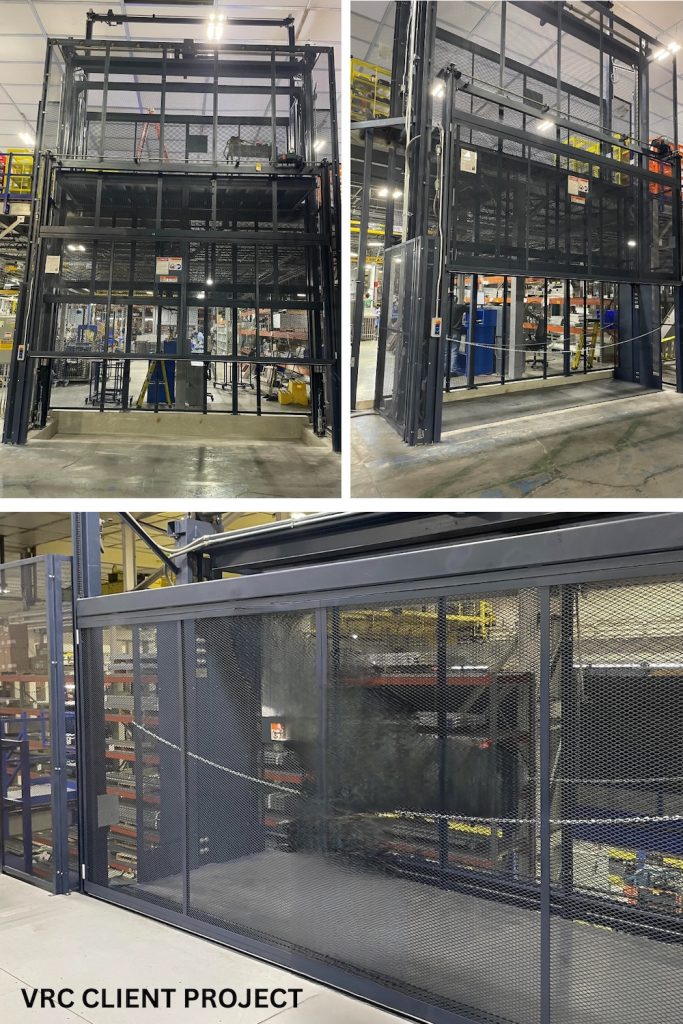

Heavy-Duty Vertical Reciprocating Conveyor (VRC) Freight Elevator Installation in Oklahoma

W.W. Cannon recently completed a heavy-duty vertical reciprocating conveyor (VRC) installation for a client in Oklahoma, providing a safe, efficient material lift that solved both capacity and safety concerns. This turnkey solution functions as a freight elevator, specifically engineered for moving goods—not people—between levels in a warehouse setting watch this video to see how it works!

Built to handle demanding daily use, this VRC freight elevator delivers long-term durability, user-friendly operation, and full compliance with safety regulations—all while meeting the client’s exact material handling needs.

What Is a Vertical Reciprocating Conveyor (VRC)?

A vertical reciprocating conveyor is a type of freight elevator designed solely for the vertical movement of materials. Think of it as a horizontal conveyor rotated upright—capable of lifting pallets, carts, bins, and other goods between floors. Unlike passenger elevators, VRCs are “no rider” lifts, meaning they are exclusively used for transporting materials.

VRCs are ideal for warehouses and industrial facilities that need a reliable material lift without the added cost or complexity of traditional elevator systems. They offer a space-saving, cost-effective way to enhance operational efficiency and improve vertical logistics.

Custom Material Lift Design for Mezzanine Access

The client needed a more robust freight elevator system to move a variety of materials between the ground level and a mezzanine in a Z-configuration layout. Their existing Autoquip VRC lacked the durability and safety features required for reliable daily operation.

W.W. Cannon engineered a custom VRC freight elevator to meet these exact requirements—improving load handling, increasing safety, and integrating seamlessly into the client’s existing warehouse layout.

Safety and Functionality Challenges Solved with a Custom VRC Lift

To address the client’s concerns, W.W. Cannon installed a 5,000-pound capacity vertical reciprocating conveyor with full caging to maximize safety. Unlike some older systems, this VRC featured powered gates that open with the push of a button—reducing manual labor and improving ease of use.

A concrete pit was cut into the floor to ensure the VRC carriage sat flush with the ground, enabling carts to roll on and off the platform without ramps or inclines. Additionally, the team resolved a major safety hazard—swinging gates interfering with forklift traffic—by installing vertically opening gates that eliminate obstructions entirely.

Mechanical vs. Hydraulic Vertical Reciprocating Conveyors (VRCs)

When selecting a vertical reciprocating conveyor, it’s important to understand the difference between mechanical and hydraulic models.

Mechanical VRCs operate using motors, chains, and gears. They’re ideal for high-cycle applications, offering faster speeds, longer durability, and more precise carriage positioning—making them perfect for facilities that run all day, every day.

In contrast, hydraulic VRCs rely on fluid pressure to raise and lower loads. These systems are more budget-friendly initially and work well for low- to moderate-frequency use. However, they often have slower cycle times and may require more frequent maintenance due to wear on hydraulic components.

The best choice depends on your application’s load capacity, cycle frequency, and budget.

Why Choose W.W. Cannon for Your Vertical Material Lift or Freight Elevator Solution?

At W.W. Cannon, we design and install complete material lift solutions, including freight elevators and VRCs, tailored to your facility’s exact specifications. From engineering to installation and ongoing maintenance, our in-house team ensures your equipment is safe, compliant, and built to last.

Whether you need to move goods between a mezzanine and ground floor or overhaul your material handling system, our team delivers customized, code-compliant solutions that maximize safety and efficiency.

Ready to upgrade your warehouse with a vertical reciprocating conveyor or freight elevator? Call us at 800-442-3061 to speak with a specialist today.

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.