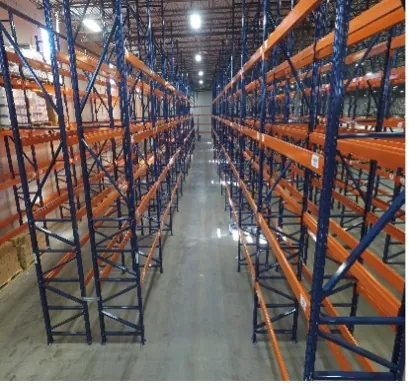

High-Density Pallet Racking Triples Storage & Saves Space in New 500,000 Square Foot Facility Pallet Racking Project in Greenville, TX

High-Density Pallet Racking Triples Storage & Saves Space in New 500,000 Square Foot Facility Pallet Racking Project in Greenville, TX

Industry: Environmental business manufacturing & supply laboratory in Greenville, Texas

Challenge: Increase storage space, safety, and organization within a new 500,000-square-foot facility

Solution: High-density pallet racking layout customized to fit their specific storage needs

Equipment: Pallet Racking from Interlake Mecalux

Result: Increased Storage capacity, organization, and productivity

Change is inevitable, particularly in warehousing, manufacturing, and distribution. Many warehouses will shift storage area missions over time. New SKUs, more inventory, and different business and operational missions can create the need for newer storage concepts. The problem? There isn’t always a place for new demands. Mohawk Labs, an environmental business manufacturing and supply laboratory client located in Greenville, TX, was in a similar situation.

Challenge: Increase storage density and organization in their brand new 500,000 square foot facility.

When confronted with the reality of keeping up with projected increases in production and volume of inventory, ultimately the company decided it was time for a new facility. Since their sister company, NCH Parts master, had already worked with W.W. Cannon on a high-volume pallet racking project, we came highly recommended. They had previously worked with Rode Chambers and had a trusting relationship with him.

Clearly, it was time for an upgrade — and W.W. Cannon was called in to help!

Solution: Custom Engineered Racking System for High-Density Storage and Increased Productivity

Rode designed a custom pallet racking system that incorporated re–purposed pallet rack from their previous facility as well as the new pallet rack required to finish out the increased space in their new facility.

“This was a custom-engineered layout,” says W.W. Cannon Sales Representative Rode Chambers. “We addressed their specific pain points.”

Result: Triple the Storage Capacity of Their Old Facility

In the end, W.W. Cannon successfully created ample storage space in the new building that facilitated a smoother production process and increased the volume of inventory able to be stored by three times the original amount. Our customer now has a stable pallet rack storage system that is up to code and can accommodate large volumes of weight, while also providing them with the versatility to modify the system based on their evolving storage needs.

Next Steps

More high-density storage, more accessibility, more safety, and more productivity. That’s what a custom-designed rack system can do for your company, and W.W. Cannon can make it happen. Download our free pallet rack guide here!

Give us a call. Let’s discuss your pain points and see how we can work together to help you!