Pallet Rack Decking

Choose from Welded-Wire, Perforated/Punched, Slotted, or Solid Steel Decking

The choice between welded-wire mesh, perforated, slotted, or solid steel pallet rack decking depends on factors such as the degree of visibility/air circulation needed, load capacity, and specific application requirements.

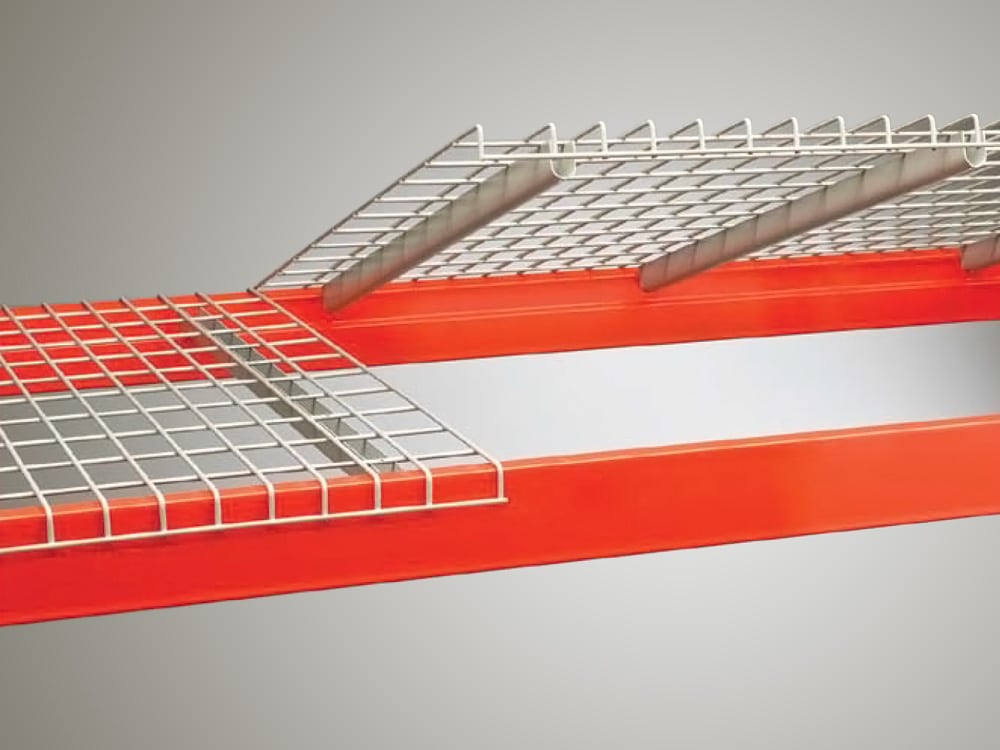

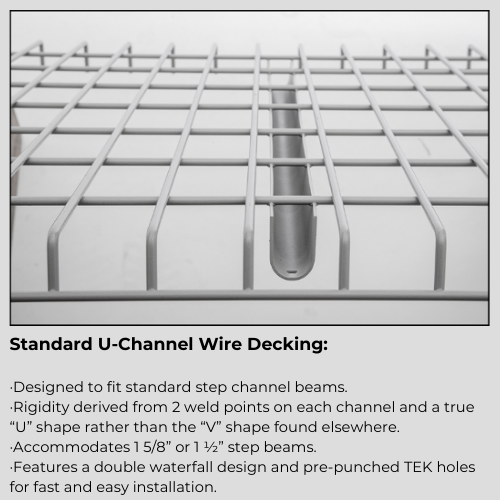

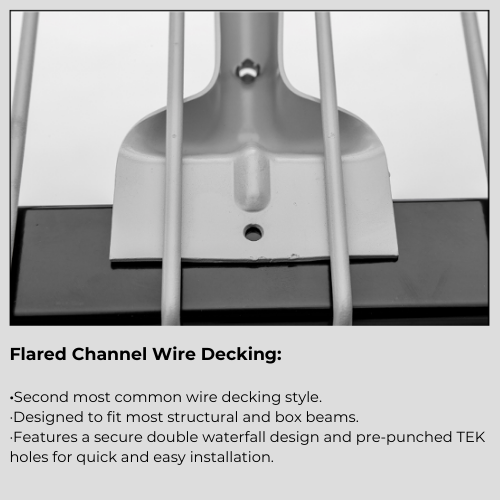

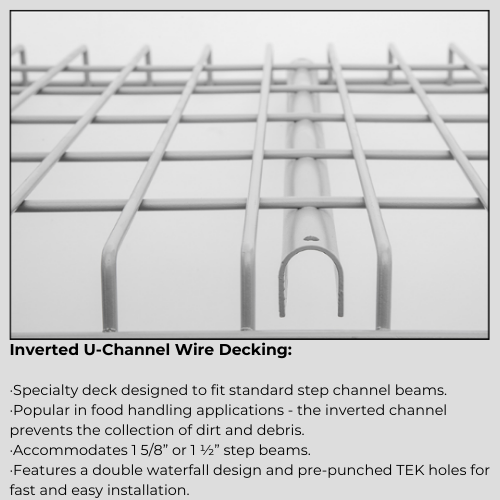

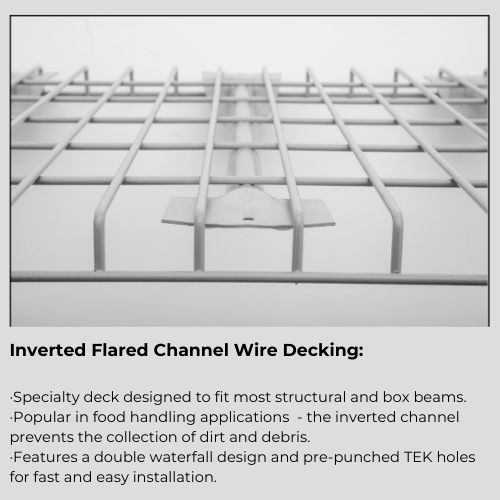

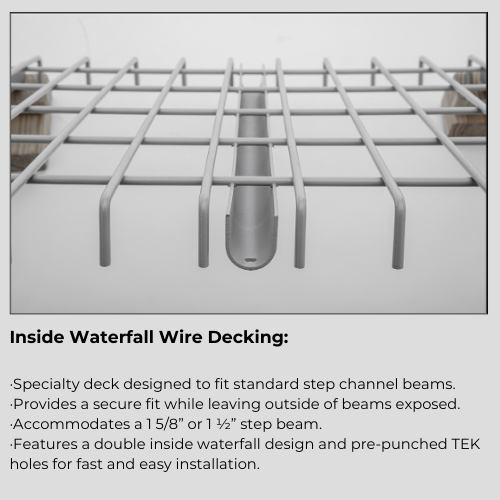

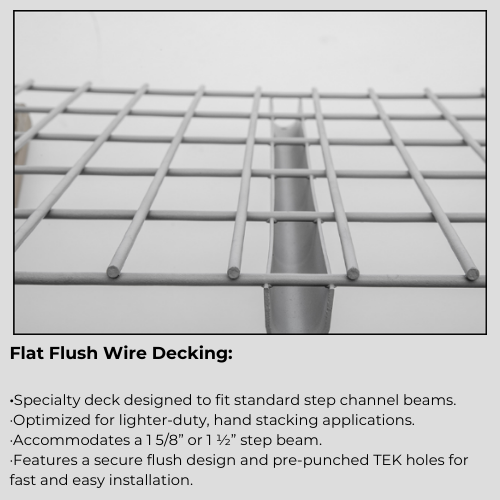

Welded-Wire Mesh Decking

Standard welded-wire mesh pallet rack decking is composed of interconnected, welded wire grids and comes in a variety of configurations. These panels are designed to sit on the horizontal beams of pallet racks, providing a stable and secure surface for pallets and products to rest on. The wire mesh design allows for easy visibility and airflow through the decking, making it compliant with ANSI MH26.2-2017 standards. Installation is easy as wire mesh pieces are prefabricated to drop into existing pallet rack beams – no tools necessary. Welded-wire mesh decking is lightweight and suitable for a variety of applications including retail, distribution, manufacturing, and e-commerce.

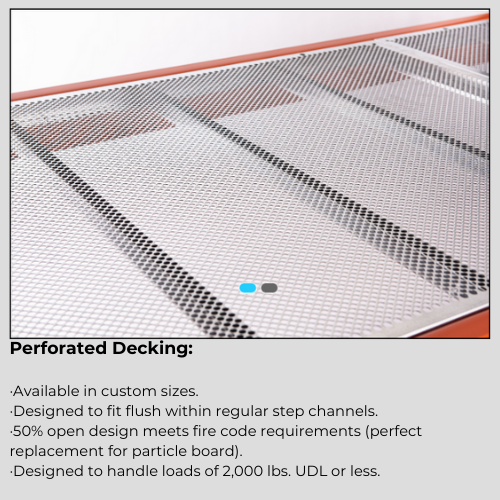

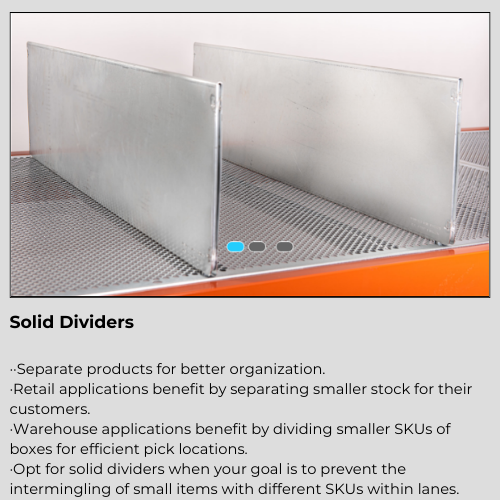

Perforated/Punched Metal Decking

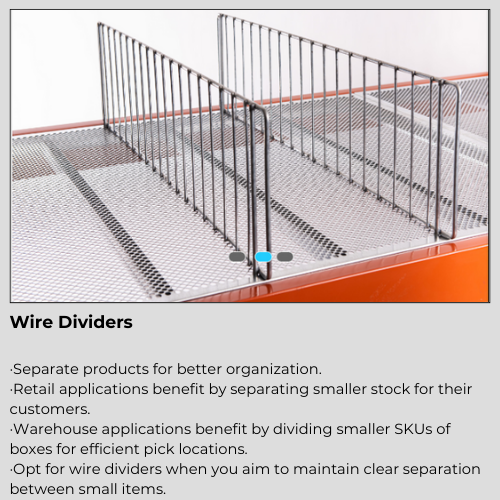

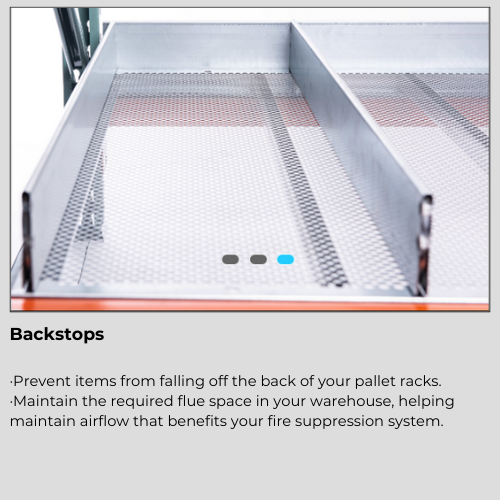

Perforated, or punched, metal pallet rack decking is composed of steel panels with evenly spaced perforations or punched holes. These panels are designed to sit on the horizontal beams of pallet racks, providing a solid and sturdy surface for the storage of pallets and products. The perforations in the decking allow for limited visibility and airflow while maintaining structural strength. Perforated metal decking is suitable for applications where some visibility is desired, but durability and strength are needed for heavy-duty applications and the storage of dense or heavy products – ensuring even distribution of loads and preventing sagging or deformation of goods. It is well-suited for heavy-duty applications across industries such as manufacturing, automotive, and high-density storage. We also offer utilitarian accessories designed to integrate with our Perforated Decking. Wire dividers, solid dividers, and backstops can be combined to create the ultimate storage solution.

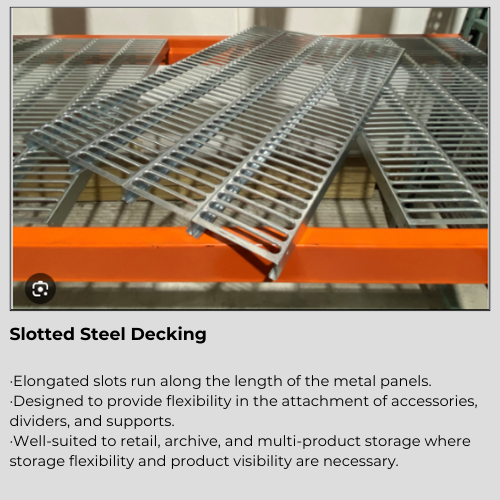

Slotted Metal Decking

Slotted metal decking features elongated slots or openings instead of evenly spaced punched holes. The elongated slots run along the length of the metal panels and are designed to provide flexibility in the attachment of accessories, dividers, and supports – which can be inserted at various points along the length of the panel. The slotted design allows for easy customization and adaptability to specific storage requirements without the need for additional modifications to the decking. It is well-suited to retail, archive, and multi-product storage where storage flexibility and product visibility are necessary.

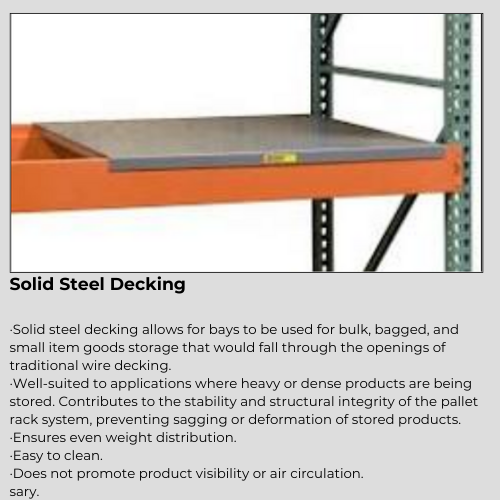

Solid Steel Decking

Solid steel decking consists of flat steel panels without perforations, holes, or openings. The panels are designed to provide a completely solid surface on the horizontal beams of pallet racks, offering maximum support and load-bearing capacity. It is well-suited to applications where heavy or dense products are being stored – contributing to the stability and structural integrity of the pallet rack system, preventing sagging or deformation of stored products, ensuring even weight distribution, and preventing items from falling through. It is also easy to clean, making it especially suitable for environments where maximum load capacity and cleanliness are priorities. In applications where security is a concern, solid steel decking provides a solid and closed surface, preventing access from below.

Photo Gallery

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.