OSHA’s Warehousing NEP: Is Your Rack Ready for Inspection?

OSHA’s Warehousing NEP: Is Your Rack Ready for Inspection?

Over the past decade, the warehousing and distribution center sector has grown substantially, with a workforce exceeding 1.9 million individuals in the United States alone. Despite this growth, there has been a corresponding increase in workplace injury, surpassing those of the broader private general industry. Certain segments within warehousing and distribution centers exhibit double the injury rate compared to the general industry.

The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) has launched a National Emphasis Program (NEP) in response to these challenges. Beyond mere injury reduction, OSHA’s innovative program is designed to elevate the health and safety standards of employees within this industry.

This blog will explore the crucial aspects of OSHA’s new NEP, shedding light on its potential impact on employers and their pallet rack safety programs. It will provide valuable tips and tricks to identify rack damage and proactively manage every aspect of the process. Is your warehouse prepared for an inspection under OSHA’s NEP? Don’t worry… We’ve got your rack!

What are industrial warehouses?

Industrial warehouses are manufacturing and storage hubs encompassing the entire production process. These facilities feature zones like manufacturing, storage, and inbound/outbound areas. They come in conventional or automated setups equipped with machinery, goods, and operational personnel. Notably, given the widespread use of racking systems, maintaining a vigilant approach through regular inspections and timely repairs is crucial to upholding safety standards and preventing potential accidents affecting personnel within these spaces.

Rack Safety challenges in warehousing and distribution centers.

The decision to implement a new NEP specifically targeting “Warehousing and Distribution Operations” underscores the seriousness of the challenges within this industry. Over the decade from 2011 to 2021, employment figures in the warehousing and distribution center sector surged from 668,900 to 1,713,900 (seasonally adjusted). However, this growth was accompanied by an increase in the incidence of occupational injuries and illnesses.

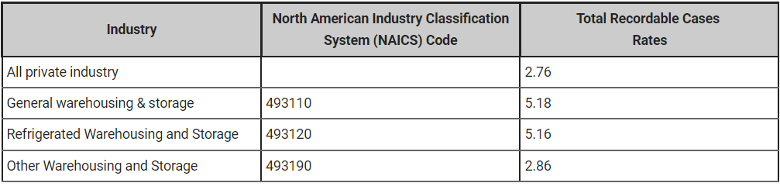

For instance, data spanning from 2017 to 2021 indicates that workers in warehousing and distribution consistently faced higher rates of nonfatal occupational injuries compared to the average rate across all private industries, surpassing even the rates observed in the construction industry.

Table 1. 2017–2021 average incidence rates of nonfatal occupational injuries in all private industry vs. the warehousing and storage industry

Enhanced Oversight and Safety Measures for High-Risk Retail Establishments.

OSHA has intensified its oversight and safety measures for high-risk retail establishments that share common hazards with warehousing and distribution facilities, particularly in loading and storage areas with racking. The NEP program specifies focused inspections for specific retail establishments with the highest injury rates, as identified through employer-reported data from 2021. The targeted establishments include:

- home centers

- hardware stores

- building material dealers

- supermarkets/grocery stores

- warehouse clubs/ supercenters.

During inspections, OSHA will prioritize loading and storage areas, potentially expanding their scrutiny if evidence, such as documented injuries, employee statements, or observations, suggests possible violations in other areas of the establishment.

Primary objectives of OSHA’s NEP

OSHA’s primary aim is to enhance safety within warehousing and distribution centers through:

- Mitigating workplace hazards.

- Proactively preventing accidents.

- Safeguarding the health and well-being of workers.

How to ready your business for an OSHA NEP inspection

Given OSHA’s increased emphasis on inspections within the warehousing and distribution sector, it is crucial for companies to be well-prepared. With inspections already underway as of October 2023, employers should proactively ensure their rack systems are up to code and compliant by following these essential tips:

- Analyze your needs in advance.

Depending on your product characteristics, one storage system may prove more fitting than another. It’s essential to be acquainted with your product details in advance, including their state (solid, liquid, or gaseous), packaging (drums, barrels, or pallets), dimensions, volume, weight, and sensitivity to external factors like light, humidity, or vibrations. This knowledge empowers you to tailor your warehouse layout accordingly. - Label your racking and shelving.

This spans from basic numerical identifiers or tags to automated systems utilizing barcodes scanned by RF scanners or robots. While these rack accessories are occasionally underestimated, they play a pivotal role in enhancing operational agility.

- Invest in routine inspection and repair services.

Routine inspections and repairs for racking systems are essential for ensuring workplace safety, compliance with regulations, and operational efficiency.

- Review your processes regularly.

Effective storage management that yields outstanding results in one season may not be applicable to a different period or campaign. It’s essential to periodically assess your industrial warehouse operations to pinpoint areas for enhancement.

Industrial warehouses stand as a vital component of the supply chain, necessitating seamless operations for a competitive advantage. Ensuring they function smoothly is crucial. Considering this, proactively staying on top of racking inspections and repairs is critical to maintaining an organized and proficient warehouse facility. Call us today, don’t wait until an accident happens!

Download our free rack damage guide. Easily identify if your rack is damaged with our simple guide.