309-3

$6,070.00

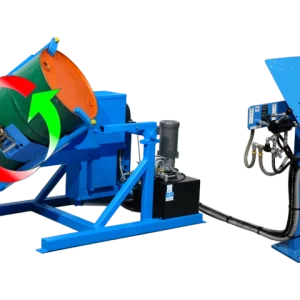

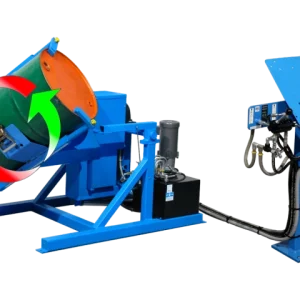

Single Drum Tumbler. 3-Phase 230/460V 50/60Hz Motor. REQUIRES Controls to Start/Stop. OSHA, CE and EU REQUIRE Enclosure with Interlock.

Key Features:

Barrel agitators to mix drum contents.

Load upright drum with your hoist and below-hook drum lifter, such as Morse model 92.

Tumble 55-gallon (210L) to 30-gallon (114L) size steel, fiber or plastic drum.

|Drum Handling SAFETY Features

- Mix right inside a closed drum

- Reduce spills, hazards and worker exposure

- Prevent messy cleanup and changeover

- Incorporate settled or stratified valuable ingredients

- Homogenize liquid, granulated or powdered products

- Eliminate sediment at the bottom of a drum

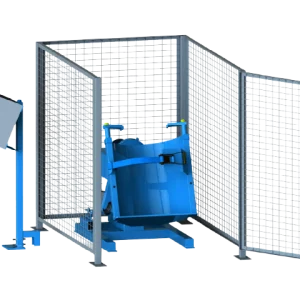

|IMPORTANT: OSHA, CE and EU REQUIRE Enclosure with Safety Interlock.

Control Package and Guard Enclosure each sold separately.

Model Features:

Model 309-3 has inverter-duty 3-phase 230/460V 60Hz motor

|Rotates drum at 14 RPM

|Add Morse Control Package for 2 to 20 RPM Variable Speed

|REQUIRES Electric Control Box to Start / Stop Rotator

|Electric Control Package sold separately

- Model CP-309-1-115 for single-phase 115V 60Hz

- Model CP-309-1-230 for single-phase 230V 60Hz

- Model CP-309-3-230 for 3-phase 208V or 230V 60Hz

- Model CP-309-3-460 for 3-phase 460V 60Hz

|Guard Enclosure Kit sold separately as model GEK-309-3

Lead Time: 25 Days

Warranty: 2 YRS

| Weight | 694 lbs |

|---|---|

| Dimensions | 72 × 42 × 46 in |