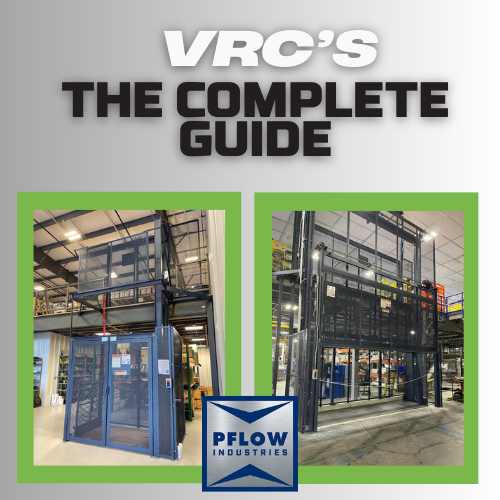

Material Lifts / VRCs

Smart, efficient way to move materials between levels and floors.

Vertical Reciprocating Conveyors (VRCs) | Material Lifts & Freight Elevators Safe, Reliable Vertical Lifts

Vertical Reciprocating Conveyors (VRCs)—also known as material lifts, freight lifts, or vertical material handling lifts—provide a safe, efficient way to move products between floors.

Call us today at 800-442-3061.

View Our VRC Solutions

Hydraulic vs. Mechanical Lifts

Not sure whether a mechanical or hydraulic VRC is right for your facility? Our comparison guide breaks down the key differences in performance, capacity, cost, and applications.

Call us today for a complimentary site visit 800-442-3061

How to Operate a VRC (Vertical Reciprocating Conveyor) | Material Lift Demo

See how a Vertical Reciprocating Conveyor (VRC) works in action—this quick demo shows just how safe and simple it is to move materials between floors.

At W.W. Cannon, we specialize in the design, installation, and maintenance of Vertical Reciprocating Conveyors (VRCs). Whether you need a mechanical or hydraulic lift, our experts will help you choose the right solution for your facility. If you’re unsure which type of VRC best fits your application, let our team guide you to the safest, most efficient option.

Download the Ultimate VRC Guide

Access this comprehensive brochure packed with details on Vertical Reciprocating Conveyors (VRCs)—including lift types, safety features, and application ideas.

Call us today for a complimentary site visit 800-442-3061

Companies Who Choose Us

VRC Applications

- Mezzanine Work Platforms

- Conveyor Systems

- Package Handling

- Multiple Story Buildings

- Indoor & Outdoor Applications

- Automotive Facilities

Authorized Dealer & Installer