Pallet Rack Safety Systems

Pallet Rack Backing: Secure and Reliable Protection

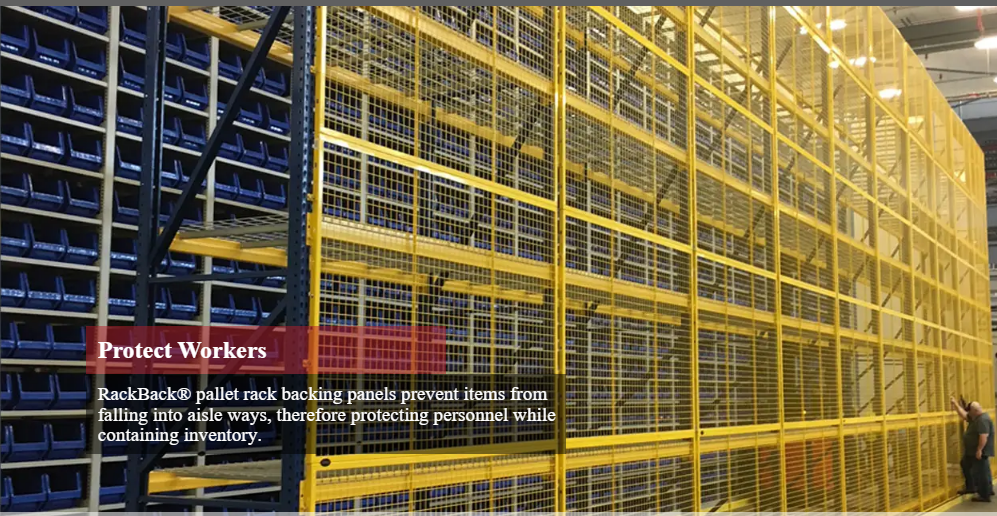

Enhance workplace safety and prevent inventory shrinkage with wire mesh pallet rack backing panels. These systems create a sturdy barrier between your employees and stored materials, reducing the risk of falling items. Unlike industrial netting that only catches materials, our steel mesh panels prevent sharp or unbalanced loads from slipping through altogether.

Pallet Rack Safety Systems

Key Features of Pallet Rack Backing Systems:

Durable Steel Mesh Construction:

Provides superior strength and protection.

Direct Mounting:

Panels bolt directly to pallet rack uprights, forming a secure wall.

Customizable Coverage:

Panels stack to the desired height (e.g., (2) 5’ high and (1) 4’ high panels for 14’ coverage).

Open Mesh Design:

Allows for visual inspection and does not obstruct sprinkler system performance.

NFPA Compliance and Fire Safety

Wire mesh rack safety systems help your company stay compliant with NFPA standards by maintaining an open flue space. Attaching steel mesh panels to back-to-back uprights ensures flames vent vertically, slowing horizontal fire spread and enabling sprinklers to effectively extinguish flames.

Flexible Design and Easy Installation

Versatile Configurations:

Available in rugged 2” x 2” x 10GA or 1 ½” x 3” x 8GA welded wire mesh.

Framed and Unframed Panels:

Choose steel angle-framed panels with predrilled mounting holes or unframed panels with offset brackets for quick installation.

Offset Brackets:

Allow for pallet overhang or flush mounting as needed.

Extension Kits:

Expand panels above racks to contain top-level loads.

Quick Assembly:

Nut-and-bolt construction simplifies installation, saving time and costs.

Pallet Rack Enclosures: Complete Security Solutions

Wire mesh panels can also be combined with mesh doors to create fully enclosed bays. These enclosures secure inventory by restricting access to valuable materials while maintaining visibility and ventilation.

Get Started Today

Protect your employees, inventory, and equipment with secure and compliant pallet rack safety systems. Contact W.W. Cannon today to schedule a consultation. From design to installation, our experts will help you create a safe and reliable rack safety solution.

Preferred Suppliers

Details

• Unlike industrial netting, these panels use steel mesh to prevent slipping of sharp or unbalanced loads.

• Panels bolt directly to existing pallet rack uprights, stacking to desired heights for coverage.

• Example: Use (2) 5’ high and (1) 4’ high panels for 14’ of coverage.

• Open mesh design allows quick visual inspection and doesn't obstruct sprinkler system performance.

• Panels maintain NFPA compliance by providing an open flue space for vertical flame venting.Vertical venting slows horizontal fire spread and ensures unobstructed access for sprinklers.

• Various manufacturers offer rugged welded wire mesh panels in steel angle framed or unframed configurations.

• Framed panels have predrilled mounting holes for flush or offset mounting.

• Offset brackets accommodate pallets overhanging the beams.

• Unframed panels are attached using offset brackets.

• Adjustable extension kits allow panels to extend above the rack to contain loads on the top beam.

• Simple nut-and-bolt assembly makes installation quick and easy, minimizing costs.

• Combine wire mesh panels and wire mesh doors to create a fully enclosed bay, restricting access to valuable inventory.

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.