Turntables

Turntables for material handling efficiency

Turntables are essential tools in material handling, designed to rotate heavy loads for improved accessibility, ergonomics, and productivity. They allow workers to easily access all sides of a load without walking around or repositioning themselves, saving time and reducing strain. Ideal for assembly lines, packaging, and work positioning, turntables simplify repetitive tasks and improve workflow efficiency. We offer turntables by Advance Lifts and Presto Lifts.

These turntables represent standard models offered by Advance Lifts and Presto Lifts. However, W.W. Cannon can also configure custom turntable solutions to meet your specific material handling needs. Contact us today to discuss your requirements and discover the best solution for your facility.

Advance Lifts Models

TML & TM Series Manual Turntables

The TML & TM Series Manual Turntables provide an economical and efficient solution for applications requiring frequent load rotation. Designed for heavy-duty material handling, these non-powered turntables offer smooth, manual rotation in both directions and are available in low-profile configurations. Built for durability, these units feature lifetime-lubricated bearings for long-lasting, maintenance-free operation.

Specifications

- Capacity Range: 1,000 – 10,000 lbs.

- Standard Platform Sizes: 30” x 30” to 85” x 85”

- Maximum Platform Sizes: 48” x 48” to 96” x 96”

- Lowered Height: 3 ½”

- Roller Radius: 9” to 29”

Key Features & Benefits

✔ Cost-Effective Alternative to Powered Turntables – Lower upfront and maintenance costs.

✔ Manual Rotation in Either Direction – Ensures flexibility in work positioning.

✔ Durable Bearing Support –

• TML Models: Ball-bearing rollers for smooth operation.

• TM Models: Cam follower roller bearings for heavy loads.

✔ Heavy-Duty Construction – Lifetime-lubricated kingpin bearing for superior durability.

✔ Customizable Rotational Limits – Optional detents, locking pins, and hard stops available.

✔ Versatile Platform Options – Standard rectangular platforms, with optional round platforms (except TML models).

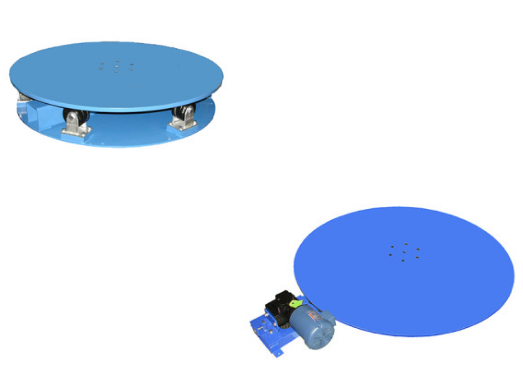

TPH &TPL Powered Turntables

The TPH & TPL Powered Turntables are designed for applications requiring frequent load rotation where manual effort would be impractical. These industrial-grade motorized turntables offer smooth and controlled rotation, making them ideal for assembly, manufacturing, and warehouse operations. Available in low-profile and high-profile configurations, these units ensure efficient and precise positioning of heavy-duty loads.

Specifications

- Capacity Range: 2,000 – 10,000 lbs.

- Standard Platform Sizes: 24” x 24” to 85” x 85”

- Maximum Platform Sizes: 48” x 48” to 96” x 96”

- Lowered Height: 9 ½” to 10”

- Roller Radius: 8” to 23 ½”

Key Features & Benefits

✔ Effortless Motorized Rotation – Reduces manual strain and increases efficiency in high-cycle applications.

✔ DC Motor & Drive Standard – Provides reliable, smooth operation (AC motors and drives optional).

✔ Clockwise Standard Rotation – Optional bi-directional rotation available with AC motor.

✔ Lifetime-Lubricated Kingpin Bearing – Ensures long-lasting, maintenance-free operation.

✔ Customizable Rotational Limits – Limit switches (+/- 3° accuracy), proximity sensors, and precision PLC control available.

Low-Profile vs. High-Profile Configurations

✔ Low-Profile Powered Turntables

• Ideal for applications requiring minimal platform height.

• Circular platforms only (rectangular platforms not available).

• Drive motor is mounted on the platform edge.

• Supported by lifetime-lubricated roller bearing cam followers.

✔ High-Profile Powered Turntables

• Best suited for applications where low platform height is not critical.

• Rectangular platforms standard, with optional round platforms.

• Drive motor is located under the platform for a cleaner look.

• Supported by inverted casters with tapered roller bearings or cam followers.

HDTM & HDTP Heavy-Duty Ring Bearing Turntables

The HDTM & HDTP Series Heavy-Duty Ring Bearing Turntables provide exceptional load handling for applications requiring quick, precise rotation of heavy loads with high edge loading expectations. Designed for demanding industrial environments, these non-powered and powered models offer superior durability, smooth operation, and precise positioning. Available in standard or reinforced platforms, these turntables accommodate even the most unevenly distributed loads while minimizing platform deflection.

Specifications

- Standard Platform Capacities

- Non-Powered: 7,000 & 10,000 lbs.

- Powered: 5,000, 7,000 & 10,000 lbs.

- Standard Platform Sizes: 48” x 48” to 120” x 120”

- Lowered Heights:

- Non-Powered: 5 ⅝” and 8”

- Powered: 17” and 18 ⅞”

Non-Powered Ring Bearing Turntable Features

✔ Heavy-Duty Ring Bearing Support – Ensures smooth, even rotation under heavy loads.

✔ Lower Cost Alternative – Provides durable rotation without requiring power.

✔ Manual Operation – Load rotates with applied force, allowing control in either direction.

✔ Customizable Platforms – Rectangular (standard) or optional round platforms available.

✔ Reinforced Platform Option – Supports uneven loads and high edge loading applications.

✔ Rotational Limit Customization – Detents, locking pins, and hard stops available for position control.

Powered Ring Bearing Turntable Features

✔ Motorized Bi-Directional Rotation – Clockwise & counterclockwise rotation standard.

✔ AC Motors & Drives – Provides smooth and efficient operation (DC not available).

✔ Customizable Speed Control – Low-speed (0-5 RPM) and high-speed (0-10 RPM) options.

✔ Heavy-Duty Drive Mechanism – Motor is mounted under the platform for durability.

✔ Reinforced Platform Option – Available for heavy, unevenly distributed loads.

✔ Positioning Accuracy – Optional proximity sensors (+/- 2º) and precision control PLC available.

PM & PP Series Hydraulic Lifts & Turntables

The PM & PP Series Hydraulic Lifts & Turntables provide optimized lifting and turning solutions where both functions operate independently. Designed for heavy-duty industrial environments, these units offer exceptional durability, reliability, and precision positioning. With manual and powered rotation options, they enhance efficiency, safety, and ergonomics for material handling applications.

Specifications

- Lifting & Manual Turntable Models: 2,000 to 5,500 lbs. capacity

- Lifting & Powered Turntable Models: 1,800 to 10,000 lbs. capacity

- Platform Sizes:

- Manual Models: 48” x 60” to 48” x 64”

- Powered Models: 24” x 48” to 60” x 60”

- Lowered Heights: 9 ½” to 21 ¾”

- Raised Heights: 33 ½” to 64 ½”

Features & Benefits

✔ Independent Lift & Turn Functionality – Allows for precise positioning and ergonomic operation.

✔ Hydraulic Lift with Patented Platform Centering Device – Doubles or triples lift life, ensuring longevity and durability.

✔ Heavy-Duty Hydraulic Components – Machine-grade cylinders, double wire braid pressure hoses, and JIC fittings for maximum reliability.

✔ Built-In Power Unit – Single internally mounted unit for compact and efficient operation.

✔ Underwriter Laboratory (UL) Listed Controllers – Ensures compliance with safety and quality standards.

✔ High-Quality Finish – Fully primed and finished with baked enamel for corrosion resistance and longevity.

ATR Series Air Operated Lift & Turn Tables

The ATR Series Air Operated Lift & Turn Tables provide efficient, maintenance-friendly lifting and rotating solutions powered entirely by shop air—no electricity required. These lightweight yet durable units are engineered for maximum value and reliability, making them ideal for material handling, assembly, and manufacturing applications. For highly specialized requirements, custom modifications are available.

Specifications

- Capacity: 1,500 to 6,000 lbs.

- Platform Sizes:

- Minimum: 36” x 48” to 48” x 48”

- Maximum: 48” x 48” to 60” x 60”

- Lowered Heights: 10 ¾” to 13”

- Raised Heights: 34 ¾” to 37”

Features & Benefits

✔ 100% Air-Powered Operation – Eliminates the need for electricity, reducing energy costs and allowing for use in hazardous or wet environments.

✔ Patented Platform Centering Device – Doubles or triples lift life, enhancing durability and long-term performance.

✔ Heavy-Duty Components for Maximum Strength – Chrome-plated, 100,000 psi stress proof steel shafts and axles ensure exceptional load-bearing capacity.

✔ Low-Maintenance Design – Lifetime-lubricated pivot bearings and sealed ball bearing wheels minimize upkeep.

✔ Advanced Safety Features – Equipped with pressure safety relief and speed control orifice to regulate down speed in case of supply line failure.

✔ Durable Baked Enamel Finish – Corrosion-resistant coating extends the unit’s lifespan in demanding industrial environments.

Presto Lifts Models

Standard Turntables

Presto Standard Turntables are designed to streamline material handling by allowing operators to easily rotate heavy loads without manual repositioning. Built from ½” thick steel plate with radiused corners, these turntables can be mounted directly to the floor, on a fixed-height stand, or even on a scissor lift table. With options for manual or powered rotation, they provide enhanced efficiency and ergonomic benefits in assembly, packaging, and manufacturing environments.

Specifications

- Load Capacity: Up to 6,000 lbs.

- Platform Construction: ½” thick steel plate with radius corners

- Standard Height: 2¾” (manual), 9” (powered with raised stand/sub-base option)

- Rotation Control:

- 180º spring position detents

- 90º spring position detents

- 90º positive locking positioner

- Mounting Options:

- Floor-mounted

- Fixed-height stand

- Scissor lift table integration

- Additional Features:

- Turret-style bearing for heavier loads and larger sizes

- Round platforms available

- Custom platform sizes available

- Powered turntable options

Features & Benefits

✔ Ergonomic & Efficient – Eliminates the need for excessive reaching, bending, or walking around loads, reducing worker fatigue and improving productivity.

✔ Heavy-Duty Construction – 1/2” thick steel platform and robust bearing assemblies ensure long-term durability and performance.

✔ Flexible Mounting Options – Can be floor-mounted, attached to stands, or integrated with scissor lift tables for maximum versatility.

✔ Multiple Rotation Control Options – Spring detents and locking positioners allow for precise positioning and stability during operation.

✔ Customizable to Fit Your Needs – Available in various sizes, configurations, and powered models to meet unique application requirements.

AXR Series Turntable Lifts

The AXR Series Turntable Lifts combine pneumatic lifting power with an integrated turntable platform, enabling workers to rotate loads for full access without excessive walking or repositioning. Ideal for manufacturing, assembly, and palletizing applications, these air-powered lift tables help increase efficiency and improve ergonomics by reducing strain and unnecessary movement.

Specifications

- Capacities: 1,000, 2,000, and 4,000 lbs.

- Raised Heights: 32” and 35”

- Lowered Height: 11”

- Vertical Travel: 21” and 24”

- Base Sizes: 36” x 48” and 48” x 48”

- Platform Sizes: 36” x 48” to 48” x 60”

- Air Requirements: 80 PSI at 15 CFM

Features & Benefits

✔ Integrated Turntable Platform – Rotates easily using anti-friction bearings, allowing workers to access all sides of the load without excessive reaching or repositioning.

✔ Ergonomic & Productivity Boosting – Reduces worker fatigue by keeping items within easy reach, making it ideal for palletizing, assembly, and workstation tasks.

✔ Durable Solid Steel Turntable – Fabricated from heavy-duty steel plate, providing long-lasting performance under demanding conditions.

✔ No Electricity Required – Operates entirely on shop air, eliminating the need for electrical connections and reducing maintenance.

✔ Customizable Control Options – Comes standard with a pedestal control, with foot controls available as an option for hands-free operation.

✔ Built-In Safety & Reliability – Includes a pressure relief valve and lifetime warranty on the actuator, ensuring safe, dependable operation.

AXSR Series Heavy-Duty Turntable Lifts

The AXSR Series Heavy-Duty Turntable Lifts provide high-capacity lifting with an integrated turntable platform, enabling easy 360-degree load access without excessive walking or repositioning. Designed for manufacturing, assembly, and palletizing applications, these air-powered lift tables improve efficiency, ergonomics, and safety by keeping work within a comfortable reach and reducing unnecessary movement.

Specifications

- Capacities: 2,000, 4,000, and 8,000 lbs.

- Platform Sizes: 36″ x 48″ up to 48″ x 60″

- Lowered Height: 15″

- Raised Height: 39″

- Vertical Travel: 24″

- Turntable Construction: 1/2″ solid steel plate

Features & Benefits

✔ Integrated Turntable Platform – 360-degree rotation using a heavy-duty steel turntable, allowing workers to access all sides of the load without excessive reaching or walking.

✔ High-Capacity & Heavy-Duty Design – Built for demanding industrial environments, supporting loads up to 8,000 lbs.

✔ Ergonomic Work Positioning – Enhances safety and productivity by keeping tools and materials within easy reach, reducing worker strain and fatigue.

✔ Durable Solid Steel Construction – Reinforced turntable and lift platform for long-lasting reliability under heavy use.

✔ Air-Powered Operation – Requires no electricity, operating entirely on shop air for maintenance-free performance.

✔ Compact, Space-Saving Design – Low-profile structure fits into tight workspaces, making it ideal for assembly lines, packaging stations, and material handling applications.

Low Profile Turntable / Roll-On Turntable

The Presto Low-Profile Turntable (LPT) sits just 7/8″ above the floor, allowing hand pallet trucks to roll directly onto the platform for easy pallet placement and removal. This design eliminates manual repositioning and allows workers to rotate pallets effortlessly, ensuring that loading and unloading always happens from the nearside—minimizing strain, reducing unnecessary walking, and improving overall efficiency.

With a 4,000 lb. capacity, a locking 43 ⅝” disc turntable, and a tapered edge for smooth pallet truck access, this turntable enhances workflow without requiring floor lagging, making it easy to relocate and use in multiple work areas.

Specifications

- Capacity: 4,000 lbs.

- Lowered Height: 7/8″

- Turntable Diameter: 43 ⅝”

- Overall Diameter: 48 ⅝”

- Unit Weight: 250 lbs.

- No Floor Lagging Required – Portable and easy to move

Key Features

✔ Hand Pallet Truck Compatible – Easily roll pallets onto the turntable for placement or removal.

✔ Ergonomic & Efficient – Rotates pallets so workers always load/unload from the near side.

✔ Eliminates Walking & Strain – Prevents the need to walk around or manually reposition heavy pallets.

✔ Locking Turntable – Secures in place when rotation is not needed.

✔ Portable & Versatile – Can be moved between workstations without floor lagging.

Ring Floor-Mount Turntable

The Presto Ring Floor-Mount Turntable (RFT-43) is a two-piece, anti-friction bearing turntable designed for efficient manual pallet loading and unloading. By allowing workers to rotate pallets effortlessly, it eliminates the need for walking around or repositioning heavy loads, significantly improving workflow efficiency and ergonomics.

With a 4,400 lb. capacity and a compact 70 lb. design, this turntable is highly portable and can even be mounted on a fixed-height platform. It is ideal for use with forklifts or stackers, while those needing hand pallet truck access should consider the Presto Low-Profile Turntable (LPT).

Specifications

- Capacity: 4,400 lbs.

- Turntable Diameter: 43 ⅝”

- Lowered Height: 2 ⅛”

- Unit Weight: 70 lbs.

- Must be fed by forklift or stacker

Key Features

✔ Full 360° Rotation – Workers can access all pallet sides from one position.

✔ Anti-Friction Bearing Design – Ensures smooth, effortless turning.

✔ Portable & Lightweight – Weighs just 70 lbs. for easy relocation.

✔ Compact & Versatile – Can be mounted on fixed-height platforms.

✔ Heavy-Duty Construction – Handles pallet loads up to 4,400 lbs.

Preferred Suppliers

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.