Dock Boards

Dock Boards | Durable, Portable Solutions for Safe Loading

Dock boards create a secure bridge between your dock and trailer for efficient material handling. At W.W. Cannon, we design, install, and repair dock boards built for lasting strength, safety, and performance — keeping your loading operations smooth and reliable.

Call us 800-442-3061

Dock Boards

What Is the Difference?

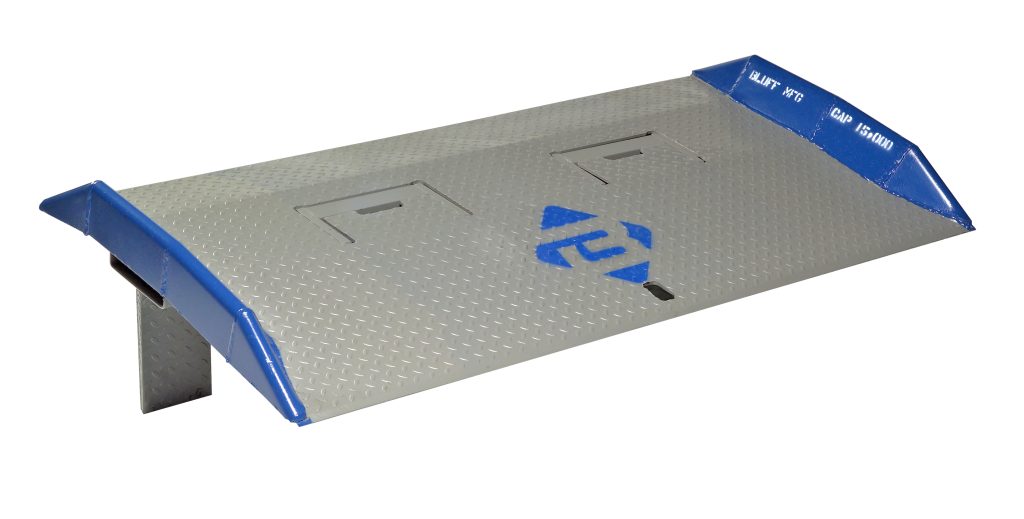

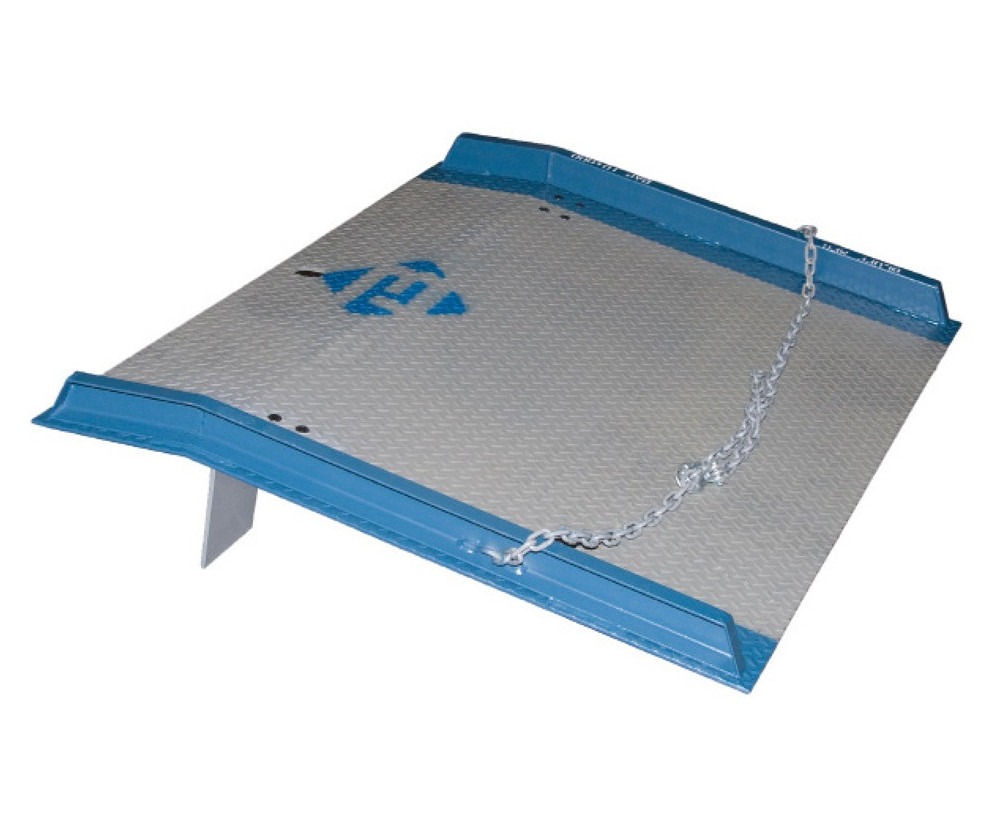

Steel Dock Boards

Built for heavy-duty applications, steel dock boards deliver maximum strength and stability for high-traffic loading areas and demanding operations.

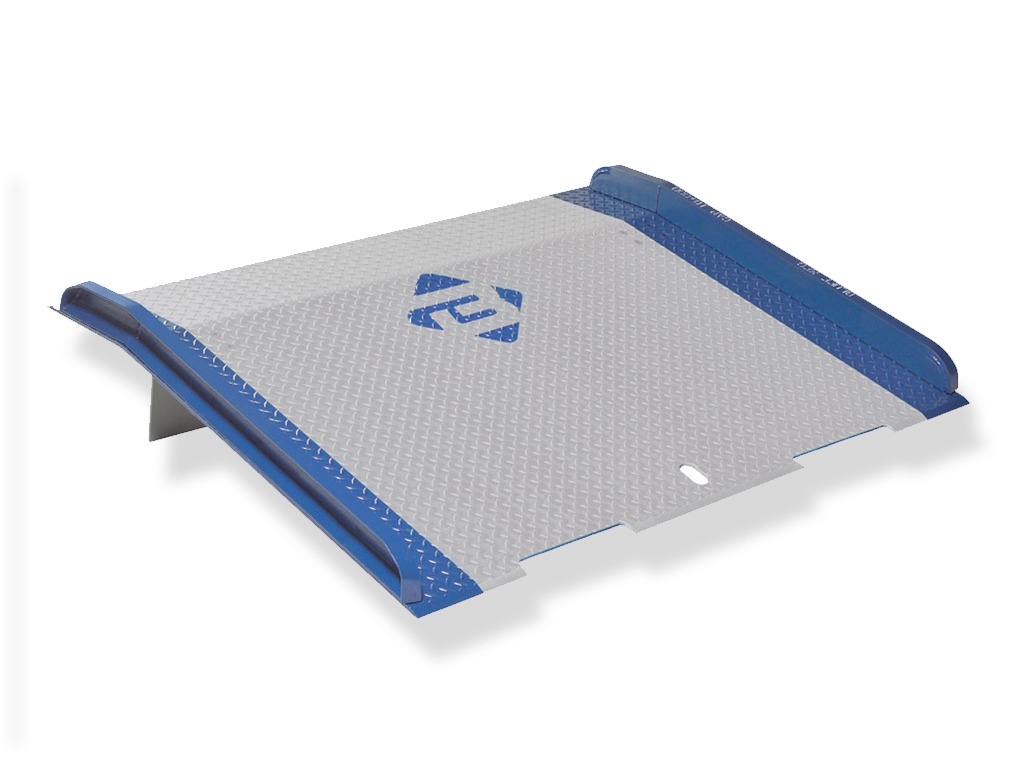

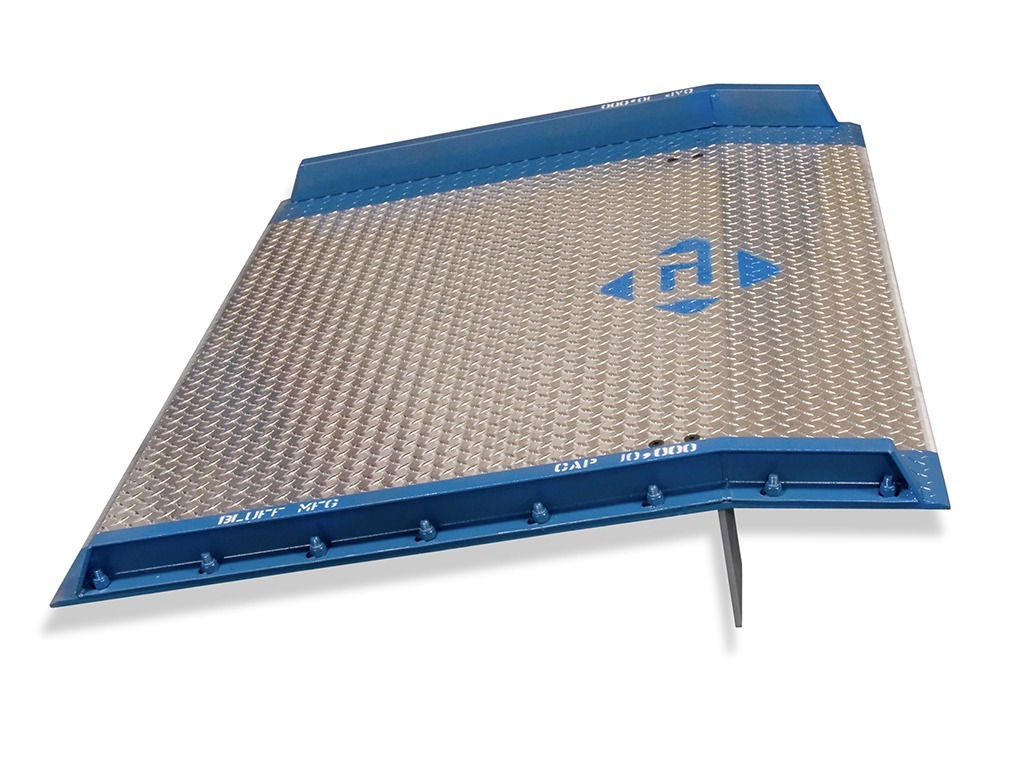

Aluminum Dock Boards

Lightweight yet durable, aluminum dock boards are easy to move and ideal for low to medium-volume docks needing portability and corrosion resistance.

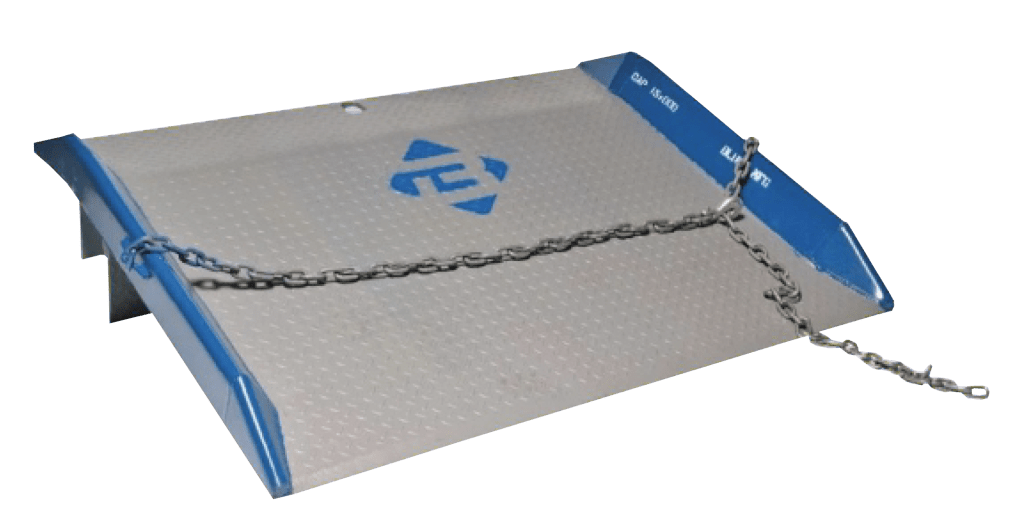

Aluminum Dock Board Models AC & AB

This video demonstrates the correct installation and use of Bluff Manufacturing’s Aluminum Dock Boards, Models AC & AB, for smooth and reliable loading operations.

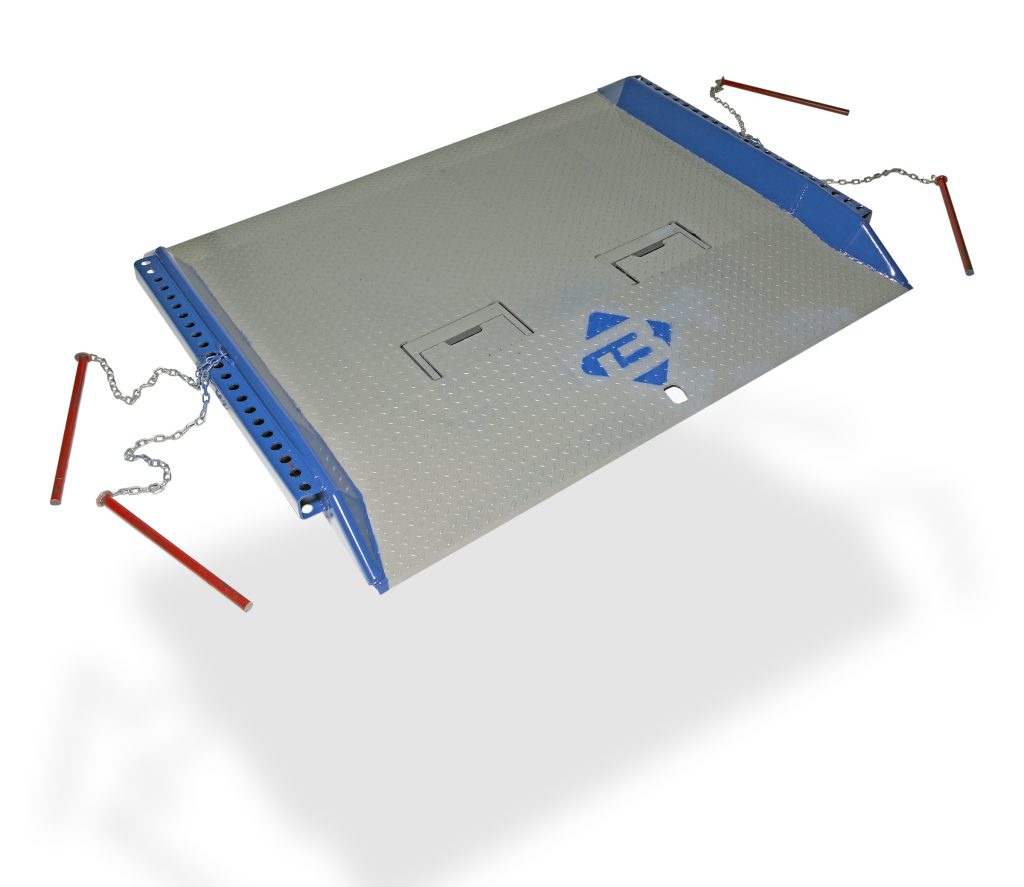

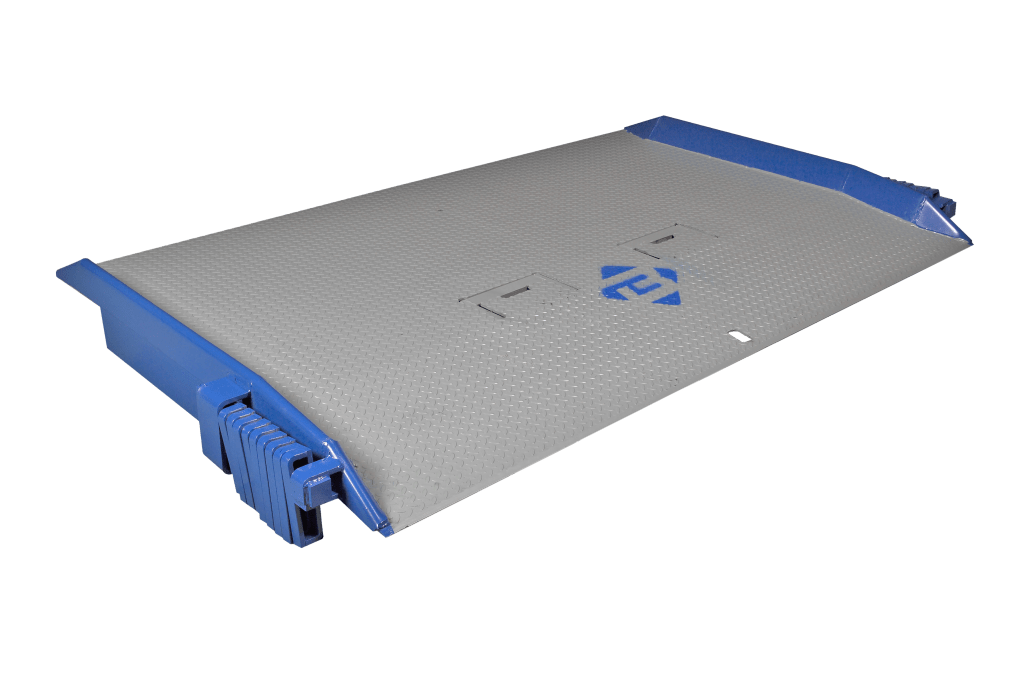

Red Pins Steel Board Model C Bluff Manufacturing 4.0

Watch how Bluff Manufacturing’s Red Pin Steel Dock Boards are installed and used — providing a safe, easy transition from dock to truck.

Companies Who Choose Us

Dock Boards Guide | Choose the Right Steel or Aluminum Dock Board

Download our Dock Boards Guide to compare steel and aluminum options — and let our experts help you select the best solution for your loading dock.

Call us today for a complimentary site visit 800-442-3061

Equipment Inspections

Equipment inspections that identify issues before they become costly problems.

Preventative Maintenance

Protect Your Investment with Regular Maintenance

Regular maintenance can extend the life of your equipment and reduce downtime. Our preventative maintenance plans are proven to reduce downtime and repair costs.

Repair & Service

W.W. Cannon offers comprehensive repair and service solutions for your business.

- 24/7 Emergency Service

- Fast Turnaround Times

- Expert Technicians

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.