Pallet Rack Repair, Inspection & Safety Solutions

Your turnkey partner for rack repair, inspection, engineered drawings & labels

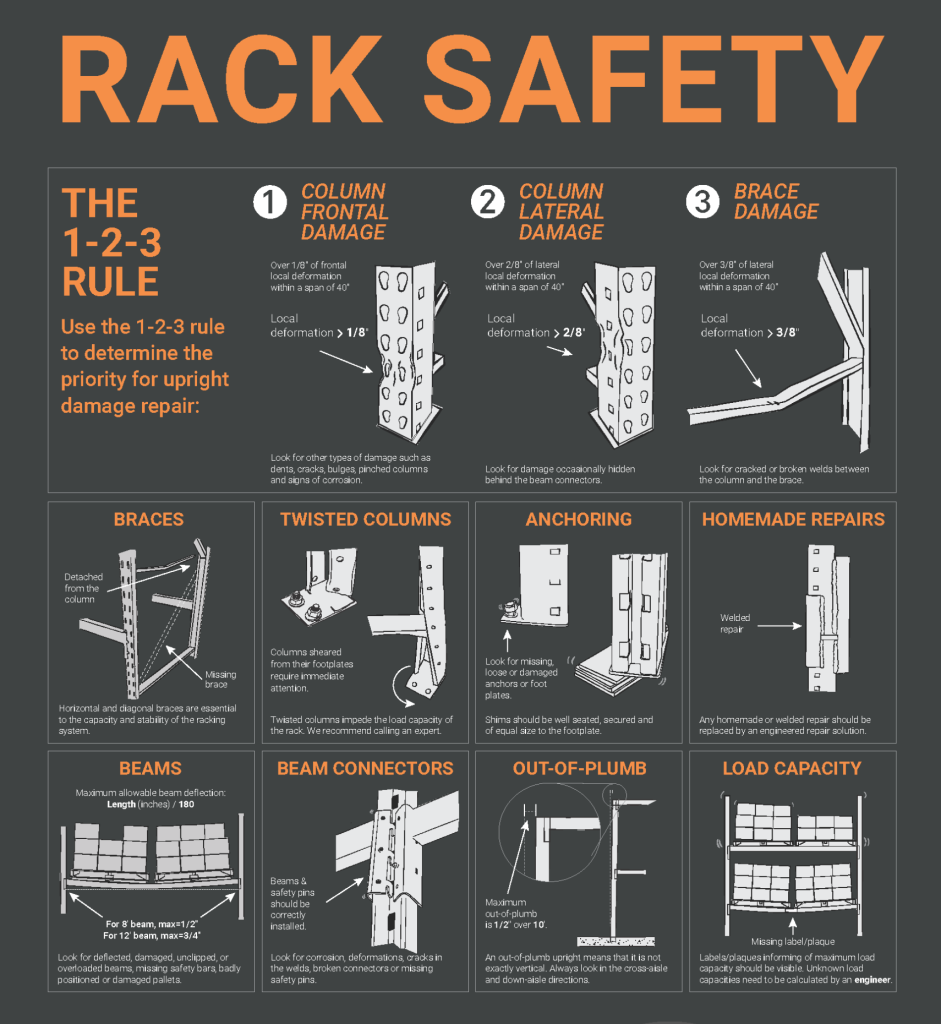

Is Your Racking System Safe?

Unsafe racks lead to costly accidents and downtime.

Use our quick-reference Rack Safety Guide to spot potential damage and protect your facility.

For a full, professional rack inspection, Call us today 800-442-3061

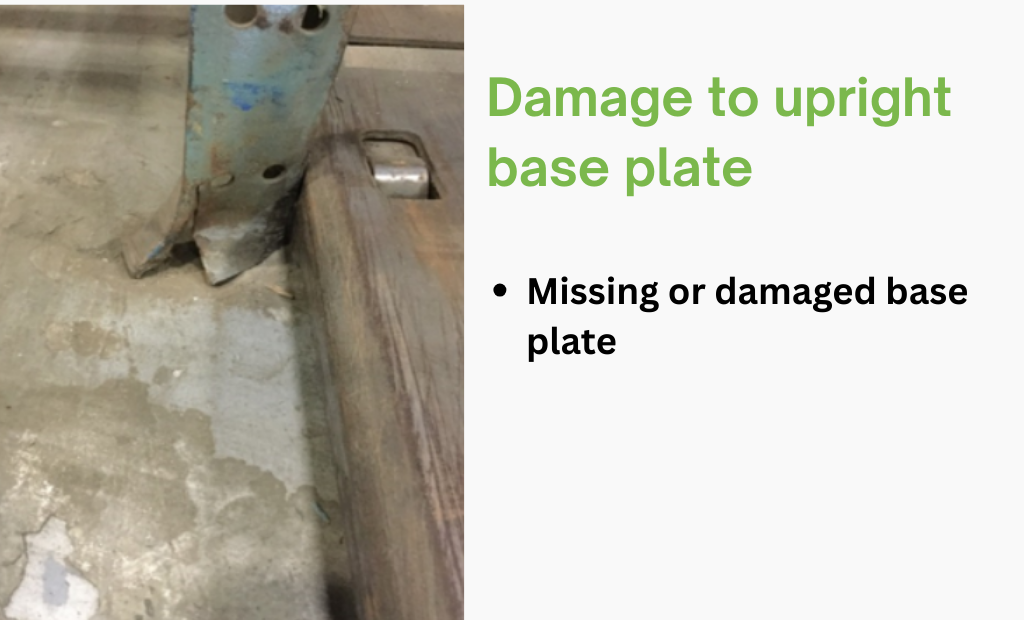

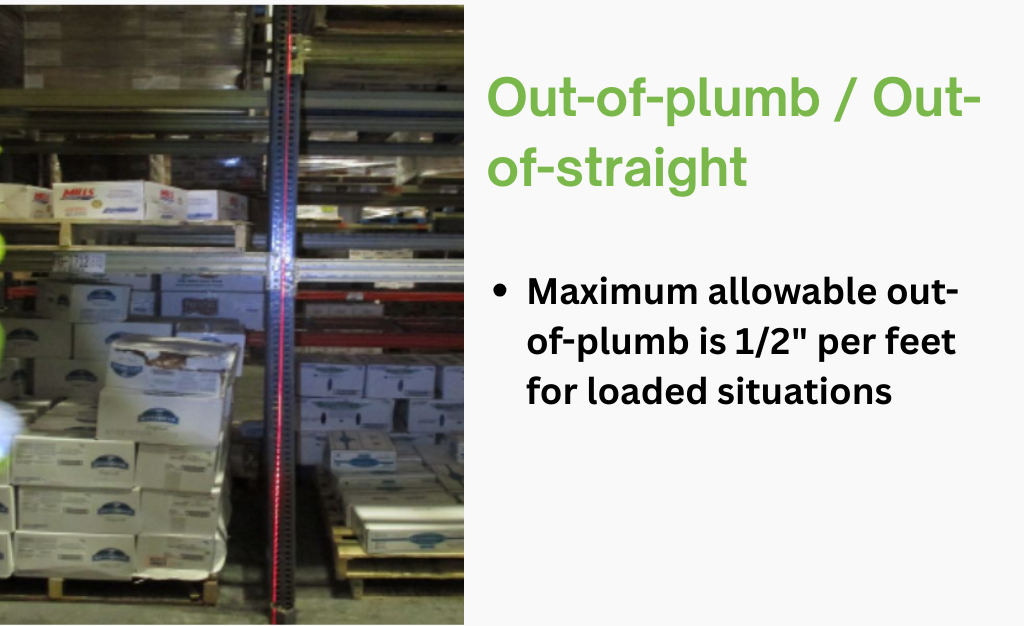

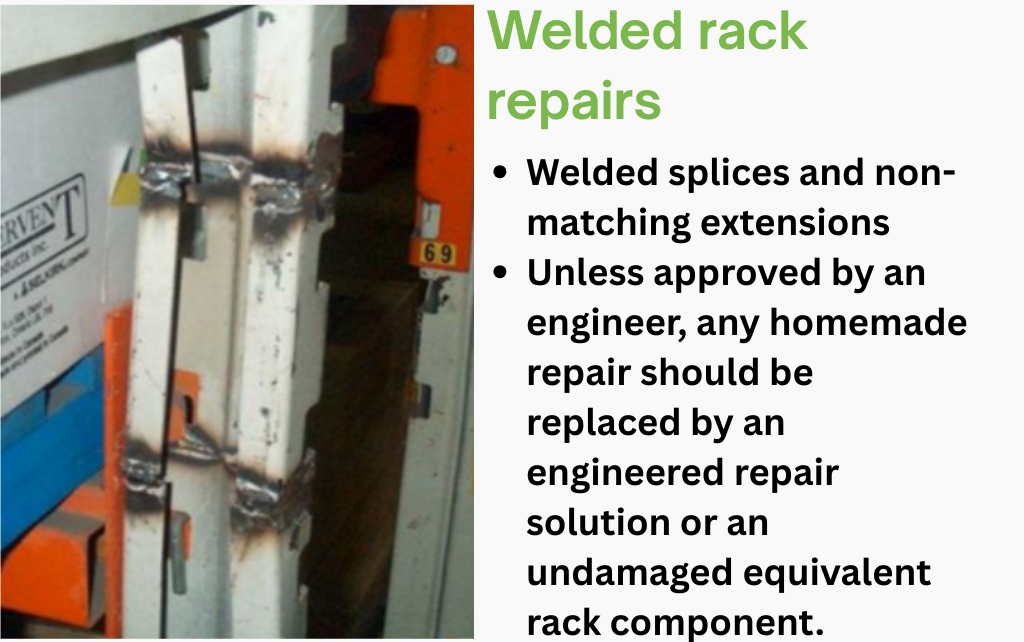

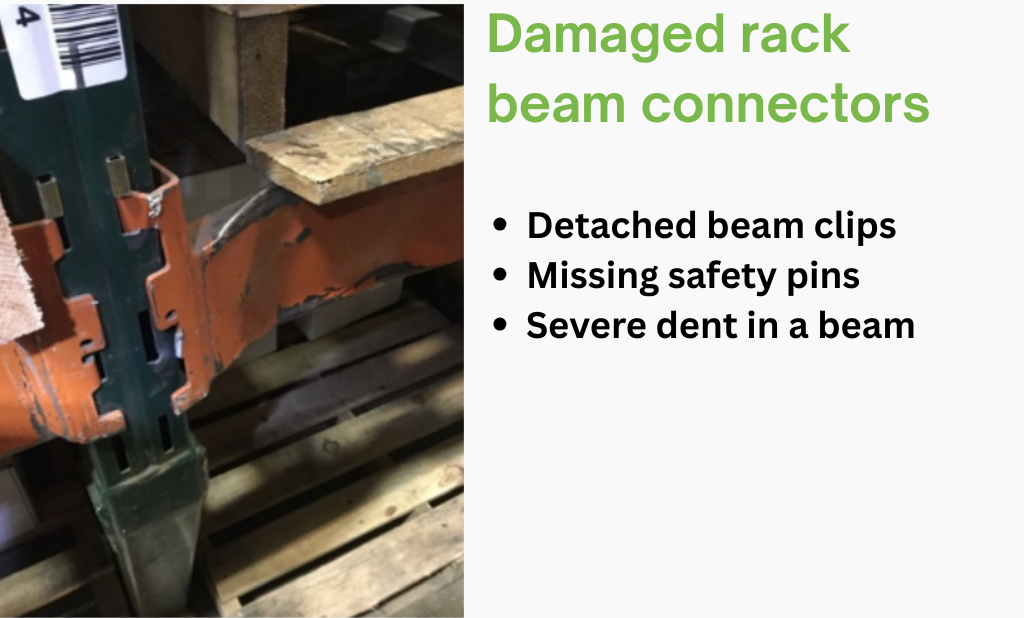

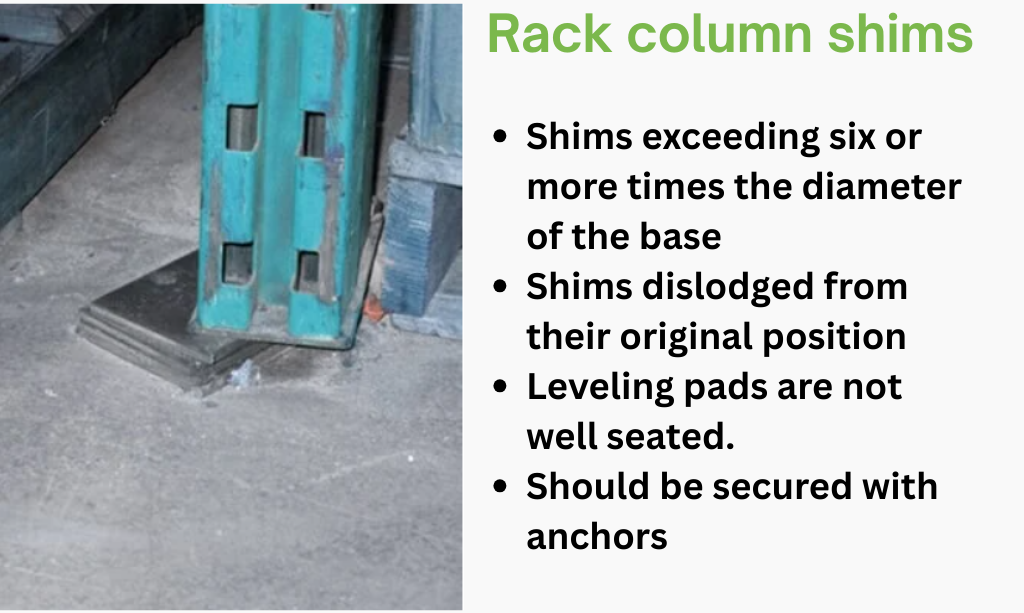

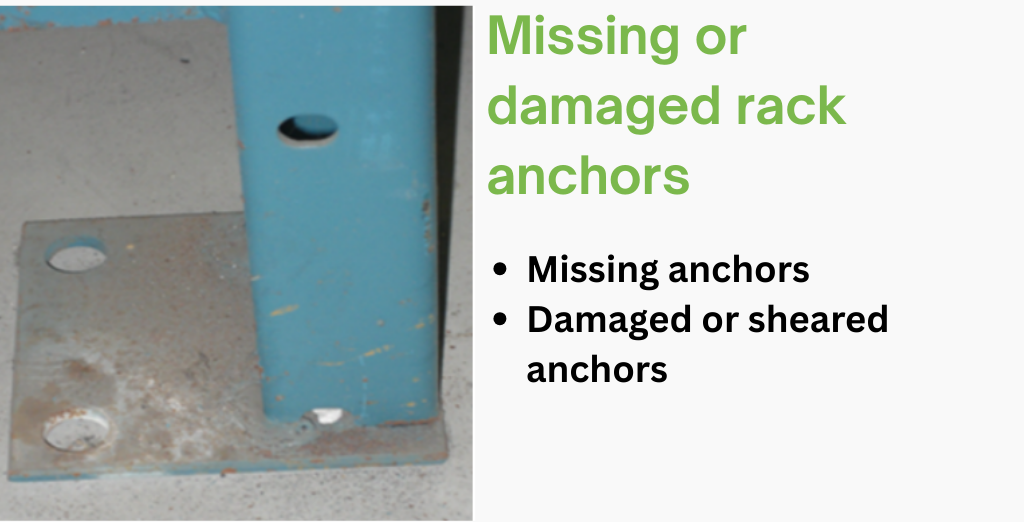

Rack Damage Examples

Pallet Racking Repair

Don’t Let Rack Damage Lead to OSHA Penalties or Warehouse Injuries — Repair It Now

Keep your warehouse safe, compliant, and running at peak efficiency with W.W. Cannon’s pallet rack repair and inspection services. We are a true turnkey provider — delivering everything from expert inspections and engineered load testing to precision repairs, protective solutions, and new rack installations.

Authorized Dealer

As an authorized partner of Damotech — North America’s largest and most trusted rack safety and repair company — we bring you the industry’s most reliable, cost-effective, and non-disruptive solutions for maintaining your rack systems. Damotech has safeguarded warehouses for over 35 years, helping facility managers protect both people and products through proven rack repair, protection, compliance inspections, and advanced inspection management software.

Inspect, Repair, Maintain & Install

1. Inspection

We perform thorough rack inspections to identify potential hazards before they become costly problems. Our inspections follow ANSI/RMI guidelines and local safety regulations, helping you remain compliant and reducing your liability.

2. Repair

Damotech’s rack repair kits restore the full structural integrity of damaged uprights and frames without the need for complete rack replacement. This not only saves time and money but also minimizes downtime in your operations. Our certified installation team ensures every repair meets or exceeds current rack safety standards.

3. Load Testing & Engineered Drawings

Our load capacity testing and professionally stamped engineered drawings give you documented proof of your rack system’s capabilities. This ensures safe usage, avoids overloading, and supports compliance during safety audits.

4. Installation

Whether you need a new rack installation, a complete safety retrofit, or protective accessories like guard rails and post protectors, we handle the project from start to finish. By combining our expertise with Damotech’s proven technology, we deliver solutions that keep your racks in service longer and your warehouse safer.

Certifications and Accreditations

.

Tell Us About Your Rack Needs

Get in touch with one of our specialists today for maintenance and repair consultation. We’ll help design a plan that’s right for you.