Cranes, Hoists & Specialized Lifting Devices

Improve workflow efficiency, prevent employee injuries, and reduce floor congestion with Cranes, Hoists, and Lifting Devices

From 50 pounds to 100+ tons: overhead lifting solutions for every application.

Cranes, Hoists, and Specialized Lifting Devices are a team working together to make material handling safer, more precise, and more efficient.

Here’s a breakdown of each component’s role and how they work together:

Types of Lifting Device Solutions We Offer

Cranes, Hoists, and Specialized Lifting Devices

- Cranes: The Overarching Structure for Horizontal Movement

- The crane is the main framework, providing the ability to move loads horizontally across a facility. Cranes can be stationary or mobile, and they operate within defined areas, like over a production line or warehouse aisle.

- Different types of cranes (like bridge, gantry, jib, and workstation cranes) offer varied movement ranges, allowing for the lifting system to reach and service different parts of a workspace.

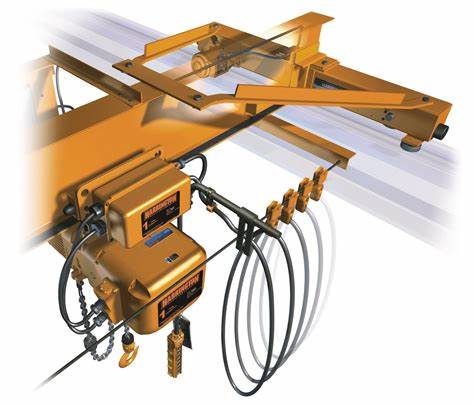

- Hoists: The Core of Vertical Lifting

- The hoist attaches to the crane, providing the lifting and lowering function. It’s what actually does the heavy lifting vertically, using chains, ropes, or cables.

- As the crane moves the hoist horizontally across the workspace, the hoist can lift, hold, or lower the load as needed, giving the operator precise control over placement.

- Different hoist types (manual, electric, pneumatic) can be selected based on the operational environment, ensuring that they meet specific lifting requirements safely and efficiently.

- By keeping the load secure and using controlled lifting speeds, the hoist reduces the risk of dropping or swinging loads, enhancing both safety and load control.

- Lifting Devices: Specialized Attachments for Specific Loads

- Lifting devices, such as slings, spreader bars, and load-positioning tools, are added to the hoist’s hook or attachment point to handle specific loads or improve load control. For example:

- Spreader Bars: Help balance long or uneven loads, distributing weight evenly and preventing tipping.

- Lifting Magnets or Vacuum Lifters: Used for handling metal sheets or other specialized materials without damaging the surface.

- Slings or Grips: These secure irregularly shaped or delicate loads, ensuring they stay stable and safe during lifting.

How They All Work Together:

When combined, these elements create a system that can lift, move, and place heavy or awkward loads precisely and safely:

- The crane provides a mobile platform that moves the load across the workspace.

- The hoist lifts and lowers the load within the crane’s range, giving vertical control.

- Specialized lifting devices make it easier to handle various types of loads safely, giving flexibility to lift everything from large equipment to delicate materials.

Example Scenario:

Imagine a manufacturing facility with an overhead bridge crane and hoist system equipped with a spreader bar:

- A worker secures a large, heavy component to the spreader bar, which balances the load.

- Using the crane, the worker moves the hoist horizontally above the desired area.

- The hoist then raises or lowers the component as needed, and the load is placed with precision in its designated spot.

This coordinated system reduces manual handling, increases safety, and allows for fast, accurate load positioning—essential for keeping operations efficient and safe.

At W.W. Cannon, we offer a comprehensive range of cranes, hoists, and specialized lifting devices designed to make heavy or repetitive lifting safer, reduce injury risks, and boost productivity by handling loads with precision and ease. Have questions or need guidance? Our solutions experts are here to help! Check out our informational brochures and give us a call or Contact Us and let our knowledgeable staff guide you through the selection process. We also offer annual preventative maintenance plans and crane inspection services to keep your crane systems in top working condition and OSHA compliant.

Industries

- Automotive

- Distribution & Warehouse

- Ecommerce & Retail

- Third Party Logistics

- Food & Beverage

- Manufacturing

- Third Party Logistics

Preferred Suppliers

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.