General Industry Fall Protection Systems

Permanent and Portable Gantry Systems

Engineered rigid rail systems for superior fall protection and safety compliance

Workplace falls are one of the leading causes of serious injury and death, costing U.S. businesses billions annually in fines, lawsuits, and medical expenses. As fall-related incidents rise, OSHA is tightening enforcement and increasing penalties for noncompliance. Per OSHA regulations, employees working at heights of 4 feet or more in general industry must be protected by a compliant fall protection system. But not all systems are created equal—you need a solution tailored to your environment.

General Industry Fall Protection Systems

What is Tether Track?

Gorbel’s Tether Track™ systems deliver OSHA- and ANSI-compliant fall protection using an enclosed rigid rail design that boosts both safety and productivity.

The enclosed track system ensures smooth, consistent movement by preventing dirt and debris buildup—unlike open I-beam systems that require frequent cleaning. A cold-rolled steel track with a tapered flange keeps the trolley centered, allowing it to move effortlessly with the worker instead of dragging or locking up.

Available in multiple styles and configurations, Tether Track systems are ideal for maximizing fall safety and efficiency in industrial environments.

Why Choose Gorbel’s Tether Track Rigid Rail Fall Protection System?

Gorbel’s Tether Track™ Rigid Rail Fall Protection Systems offer a safer, more efficient alternative to horizontal lifelines—especially in elevated work environments with low headroom. These OSHA-compliant systems allow workers to move freely and pass one another without disconnecting, reducing fall risk during transitions. With fewer supports needed, Tether Track reduces material and installation costs, supports multiple workers without interference, and installs with no structural modifications required. It’s a cost-effective, low-maintenance solution for high-risk applications

Tether Track™ systems are available in two primary configurations—each suited to specific space and structural requirements:

Ceiling-Mounted Systems

Mounted parallel or perpendicular to ceiling beams, these systems use the building’s structure for support. For facilities with overhead obstructions, drop rod hangers with sway bracing can route the track below obstacles without compromising fall protection performance.

Free-Standing Systems

Ideal when no overhead structure exists or when greater flexibility is needed. These systems install using floor-mounted column supports, making them perfect for evolving workflows or open work areas. Easily reconfigured or relocated as safety needs change.

Tether Track System Configurations

W.W. Cannon offers a full range of Tether Track™ fall protection systems, each engineered to meet OSHA requirements and adapt to various work environments. Here’s a quick breakdown of available configurations:

Bridge System

Supports multiple workers on both ceiling-mounted and free-standing systems. Multiple bridges allow for simultaneous fall protection without limiting movement.

Free-Standing Monorail

Engineered for long spans and open floor layouts. Offers a single overhead fall arrest path with its own support structure—ideal for transportation and agriculture facilities.

Ceiling-Mounted Monorail

Perfect where floor space is limited. Mounts to existing structural steel and maintains an open, unobstructed floor plan. Low-profile design is ideal for tall ceilings and tight headroom applications.

Swing Arm System

Provides 180° or 360° fall protection in tight or irregular spaces. Mounts where ceilings are inaccessible and is commonly used in coal processing, food distillation, and similar industries.

Fold Away System

Deploys only when needed—then folds away to clear space. Ideal for rail yards or food processing plants where overhead crane access is essential. Keeps productivity high without sacrificing safety.

Single Pole System

When space is tight and floor obstacles are present, a single anchor point solution delivers fall protection without multiple columns. Used in truck tarping, tank car service, and other high-clearance zones.

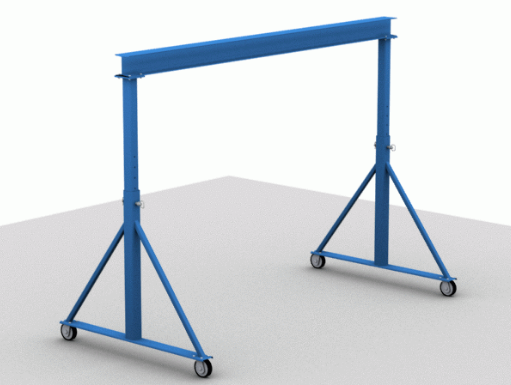

Portable Gantry System

Mobile and flexible—ideal for job sites where a permanent solution isn’t possible. Accommodates single or multiple users, then moves out of the way when not in use.

Recovery Trolley

Fall protection doesn’t end with the arrest—recovery matters just as much. W.W. Cannon offers the Recovery Trolley, designed to lock onto the track upon a fall and help workers regain control and return to the surface safely. Using the force of the fall and the worker’s weight, the rigid trolley body engages the rail to stop lateral movement, enabling efficient, self-assisted recovery. This advanced system complements our full line of OSHA-compliant fall protection solutions. For detailed specs on span, capacity, and worker configurations, refer to our product brochures or contact us for expert guidance and installation support.

Product Documents

Preferred Suppliers

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.