Crane System Accessories

Complete Your Crane System with These Accessories

W.W. Cannon offers accessories to enhance ergonomic operation and safety, and to ensure you have adequate monitoring capabilities for your crane system. Need replacement parts, equipment refurbishing/repair, preventative maintenance, or inspection services for an existing crane system? We can help with that, too!

Crane System Accessories

Pendants/Handles

Pendants, also called handles, are crucial in crane and hoist configurations as they provide operators with a safe and efficient way to control the equipment. They typically serve the following purposes:

- Precise Control: Allow operators to guide crane or hoist movements, such as lifting, lowering, or traveling, with precision.

- Ergonomic Operation: Designed for comfort, reducing operator fatigue during extended use.

- Improved Safety: Keep operators at a safe distance from the load and crane movement areas.

- Multi-Function Capability: Feature buttons or switches to control various functions like speed adjustments, directional control, and emergency stops.

- Enhanced Productivity: Enable quick and accurate load positioning, streamlining operations.

We offer both electric and pneumatic handles for use with traditional lifting equipment, as well as Intelligent Lifting Devices (ILDs). The Soft Touch Electric Control Handles are a plug-and-play solution that can be used with any electric equipment, including ILDs, and come in 1, 2, 3, and 4-lever designs. The Soft Touch Pneumatic Control Handles are a plug-and-play solution that can be used with any air actuated end effector. They come in 1, 2, 3, and 4-lever designs. All handles require less than 1.5 lbs. of depression force, reducing fatigue and repetitive stress injuries of the hand and wrist.

The In-Line Slide Handle allows the operator to get close to the load for more control and precision. The remote mount slide handle offers the same smooth control as the slide handle but accommodates set-ups where the operators can’t be close to the load.

The G-Force Pendant Control Handle is a two-button infinitely variable control handle for use with the G-Force® and the Easy Arm™ Intelligent Lifting Devices. It is an optional alternative to the standard G-Force® slide handle. The buttons of the G-Force® Pendant Control require less than one pound of force to depress, making it up to 70% easier than traditional pendants. This reduces the potential for fatigue and repetitive stress injuries of the hand and wrist.

The new Force Sensing Handles for Gorbel’s G-Force product line offer versatility in ergonomic lifting. Compared to standard slide handles, which use displacement of the handle to initiate upward or downward motion, the new design senses force applied without any handle motion. This creates a versatile option for tooling, or elongated handles that perfectly serve applications with a wide range of motion.

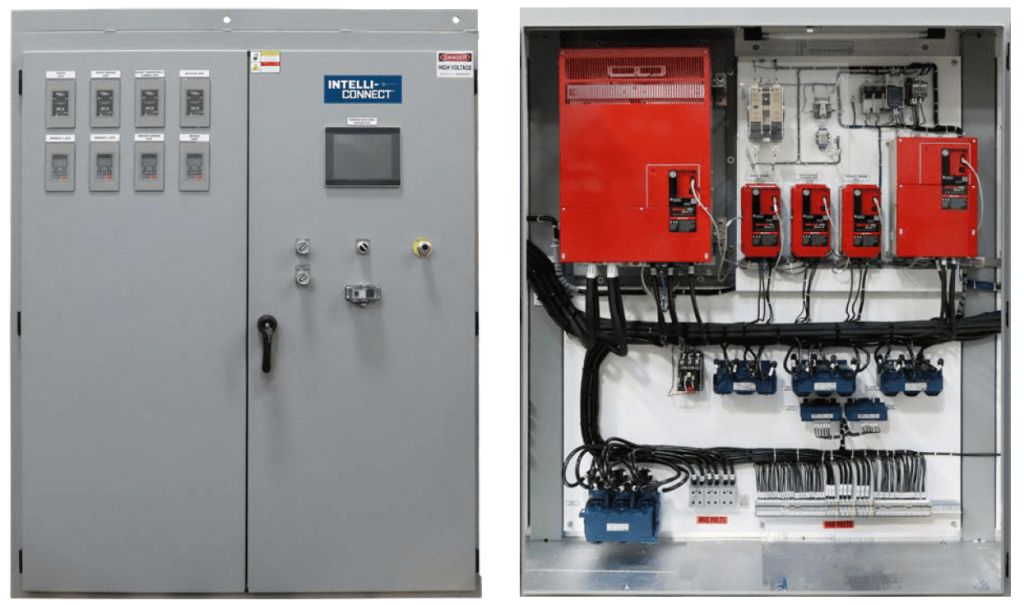

Intelli-Connect

Downtime due to unexpected maintenance or equipment failure is expensive. Intelli-Connect™ can help enable predictive maintenance and minimize downtime. Intelli-Connect diagnostics and analytics enable quick and easy programming, maintenance, monitoring, and troubleshooting of overhead cranes and hoists. Using the Intelli-Connect Mobile App, you can access detailed information right from the plant floor. With diagnostic information available at your fingertips, you can address issues more quickly, plan maintenance, and ultimately reduce downtime. Intelli-Connect is ideal for all types of overhead crane applications in industries including power generation, automotive, aerospace, metals, pulp and paper, and much more.

By incorporating this technology into your overhead crane or hoist, you can proactively monitor and schedule maintenance to ensure you have the necessary parts and support available when you need it. And, if your system does go down unexpectedly, Intelli-Connect can help reduce your mean time to recover (MTTR). With instant access to user manuals available through the app, operators can easily reference system setup and diagnostics to get equipment back up and running quickly.

From design consultation to onsite project management and installation, W.W. Cannon not only helps you select the right crane system, but we can also help you keep it running safely, ergonomically, and efficiently. Did we mention that we have decades of experience navigating the permitting and code compliance process? Mismanagement of these issues can lead to project delays, emphasizing the importance of our expertise in handling them effectively. We also install and service everything we sell. Check out our crane accessories brochures, then contact us today and let one of our experts help you accessorize your crane system – on time and within your budget.

Preferred Suppliers

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.