When Do I Need Stamped Drawings for My Pallet Rack System?

When Do I Need Stamped Drawings for My Pallet Rack System?

When Do I Need Engineered Stamped and Sealed Drawings for My Pallet Rack System?

When planning a new rack system, many people focus on buying and installing the equipment but overlook one critical step: engineered drawings. These stamped and sealed plans ensure your system is safe, stable, and code compliant and are usually required for permitting.

Does Your Rack System Need Engineered Drawings?

Short answer: yes. They are not just a formality.

What Is a Stamped (Engineered) Drawing?

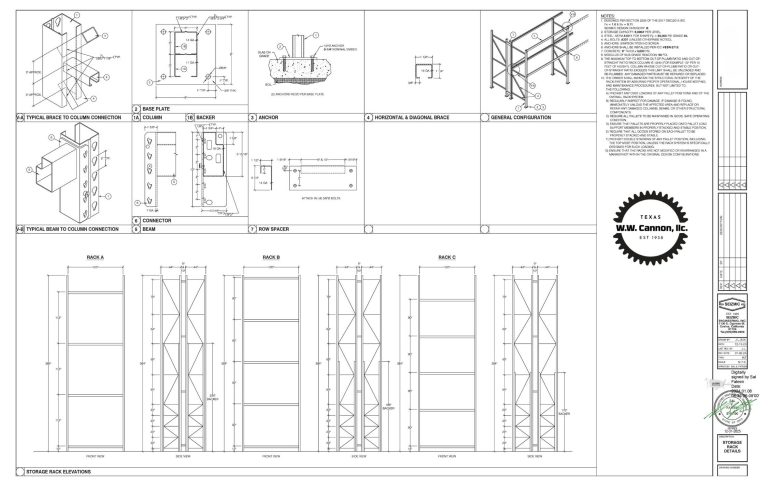

A stamped drawing is proof that a licensed engineer has designed and approved your rack system. It confirms that your setup meets structural codes, seismic requirements, and national safety standards such as RMI/ANSI MH16.1.

Even if your city does not specifically require them, stamped drawings guarantee that your rack is built correctly, safely, and to last.

Engineered Drawings

When Are They Required?

You will usually need stamped drawings if your rack system meets certain height or load thresholds.

You will likely need stamped drawings if your system:

- Is taller than 5–6 feet

- Stores materials higher than 12 feet

- Requires a building permit

These drawings show that key details such as load ratings, beam capacities, and anchoring methods have been reviewed and verified by a professional engineer.

Custom or Modified Rack Systems

If you are mixing different rack types, using pre-owned materials, or creating a custom layout, you will need stamped drawings. Once a system is modified, the manufacturer’s standard design tables no longer apply. A licensed engineer must confirm that it is still safe and structurally sound.

Seismic or High-Risk Areas

In regions with earthquakes, strong winds, heavy snow, or unstable soil, engineered drawings are mandatory. They ensure your rack system can handle environmental stress and remain secure.

Permitted vs. Non-Permitted Projects

Even if your project does not require a permit, engineered stamped and sealed drawings are strongly recommended. They help prevent accidents, rack failures, and costly damage, keeping your people and property safe.

In short:

- Permitted projects: Always required

- Tall or heavy racks: Always required

- Custom or modified layouts: Always required

- Seismic or high-risk zones: Always required

- Standard systems: Recommended for peace of mind

Stamped drawings confirm your rack is engineered for your specific use, not just close enough.

The W.W. Cannon Advantage

At W.W. Cannon, we do more than supply racks. We will handle every step of your project. From design and permitting to installation, our team works with licensed engineers to produce detailed, code-compliant engineered drawings. We take care of the details, so your system is safe, approved, and built right the first time.

Contact W.W. Cannon today to get started!

.

Schedule Your Consultation with Our Workstation Crane Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.

Companies Who Choose Us