Modular Building System Components

Prefabricated Wall Panels

Starrco offers a variety of wall panels & finishes so you can use the materials that are the best fit for your project. Don’t worry if you don’t know which options are right for you. The W.W. Cannon team is comprised of experts who can happily guide you to the ideal solution for your application, whatever that may be. If you need something outside of traditional options, just let us know & we will work with you on custom wall panel solutions.

Deluxe:

Most versatile panel. Wipeable surface is perfect for in-plant offices, breakrooms, warehouse, offices, and reception areas.

- 2″ EPS foam sandwiched between 1/2″ gypsum available in a variety of finishes (also available in mineral wool or polyisocyanurate rather than EPS foam)

- R11 insulation value

- STC 28

- Class A non-combustible

Reinforced:

Heavy-duty solution if you intend to hang heavy objects or mount fixtures on the wall panel.

- EPS foam & fire-resistant plywood sandwiched between 1/2″ gypsum available in a variety of finishes

- R11 insulation value

- STC 30

Sound Control:

Designed to create quiet in a noisy environment.

- EPS foam sandwiched between 5/8″ HD particle board and 1/8″ hardboard

- R10 insulation value

- STC 33

- Class-C combustible

High Performance:

Tongue-and-groove design enables these wall panels to be used with or without wire studs, depending on the application. Ideal for tall walls, grow rooms, exterior applications, controlled environments, etc.

- Polyisocyanurate foam with 24-gauge steel skin

- R19-R21 insulation value

- Vapor barrier

- FM approved*

- 2.63 lb/sqft making it lightweight & easy to install

- Up to 27′ tall

Cleanroom:

Polymetal panels designed for ISO-rated controlled environments, where sanitation and cleanliness are key. Ideal for any controlled environment where it is necessary to wipe down or sanitize walls.

- Insulating EPS foam core laminated between aluminum clad stabilizers

- R14.4 insulation value

- 3.2# psf

- Class-A fire rating

Wall Panel Finishes

Vinyl:

Vinyl finishes are durable, easy to clean, and provide a classic look to any modular office or building. Starrco’s vinyl finish comes standard in three colors (white, khaki, gray) and is suitable for any Starrco framing system.

Textured FRP:

Fiber-reinforced plastic (FRP) is a heavy-duty wall finish for the toughest applications. Perfect for labs, CMM rooms, & more. Starrco’s textured FRP comes standard in three colors (white, khaki, gray) and is suitable for any Starrco framing system. Smooth finish FRP is also available.

HDPE:

Waterproof plastic that acts as a barrier to prevent damage from frequent water exposure. The wall panels are puncture and tear resistant and are also UV resistant, allowing for both outdoor and indoor installations.

Painted Aluminum or Steel:

Smooth, baked-on painted finish.

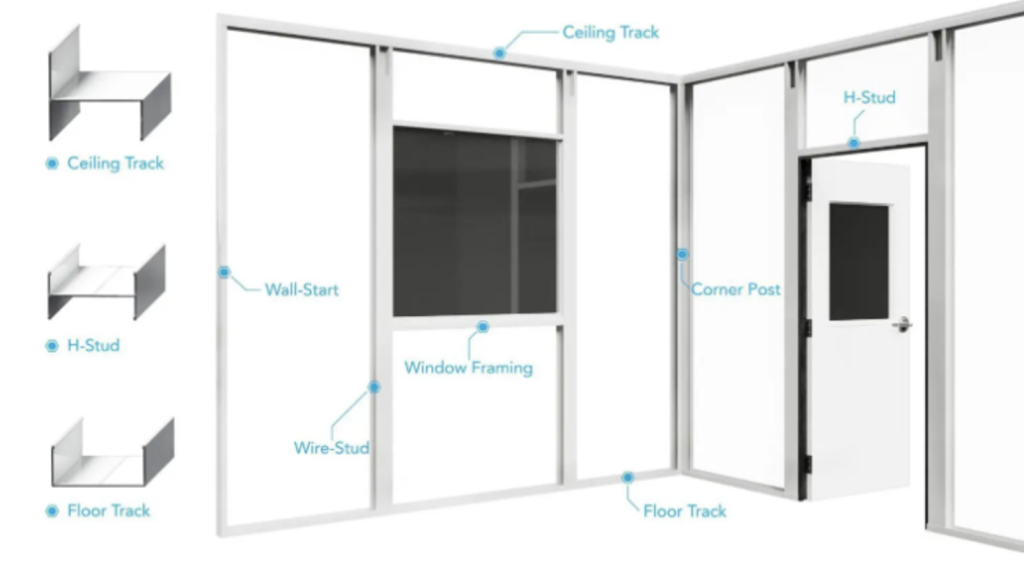

Framing Systems and Components

Starrco offers three framing systems each complete with their own benefits and advantages. All three systems come in multiple colors and are compatible with all Starrco panels & finishes. The framing systems consist of multiple types of extrusions: wire-studs, wall starts, corner posts, H-studs, window framing, floor track, and ceiling track.

Wire-studs (SS3000):

- 6063-T6 extruded aluminum

- Four-piece design allows for wiring on both sides

- Removable cover plates on both sides

- Wall height up to 13′ 3″

- Designed for maintenance load

- Resist horizontal load of #5 psf

- Allows for removable wall panel without disturbing adjacent panels (non-progressive design)

Wire-studs (SS3500):

- 6063-T6 extruded aluminum

- Three-piece design allows for wiring on one side only

- Removable cover plates

- Wall height up to 15′

- Designed for heavy storage loads

- Resist horizontal load of #5 psf

- Allows for removable wall panel without disturbing adjacent panels (non-progressive design)

Wire-studs (SS3500) with Steel Inserts:

- 6063-T6 extruded aluminum

- Three-piece design allows for wiring on one side only

- Removable cover plates

- Wall height up to 17′

- Steel insert increases wall height capabilities

- Load bearing based on building span

- Allows for removable wall panel without disturbing adjacent panels (non-progressive design)

Wire-studs – The piece that holds everything together and that sets Starrco apart.

Wall starts – Fastens to existing structure for non-freestanding applications.

Corner posts – Creates a 90-degree angle.

H-studs – Used to integrate doors into the Starrco framing system.

Window framing – Used to integrate windows into the Starrco framing system.

Floor track – Creates the layout of the structure.

Ceiling track – Acts as a ledge for corrugated roof decking – the lip conceals decking (available with or without lip).

Electrical Components

Wiring:

Starrco buildings can either be field-wired or manufactured complete with modular wiring. All modular electrical components supplied by Starrco are UL listed. The modular wiring system, including the modular lighting system, have standard components that are designed for use with a 120/240-volt single-phase system operating at 60 Hz. Components for three phase and other special requirements are available as special orders.

Starrco’s “Quick-Tric” Pre-Engineered electrical system is designed to snap together for fast and easy installation. The connections are color-coded and safety keyed to lock together in one direction making it virtually impossible to connect the system incorrectly. This unique five wire system is both U.L. and N.E.C. listed.

Specifications/Benefits:

- Components are 100% reusable.

- All components are U.L. listed and comply with N.E.C. section 604.

- System is easy to add-on to or relocate.

- Electrician is needed only to hook up power source to breaker box.

- The system snaps together quickly and can be installed while the office is being assembled.

- Spring latches hold connections securely in place.

- The system is 5 wire with 2-circuit capability.

- All wiring is 12 gauge with THHN insulation.

- A complete layout drawing and material list are supplied.

- System design complies with UL standard 183.

*Important note: A few local electrical codes do not allow Pre-Engineered electrical components. The local building inspector should be consulted prior to ordering to determine if any code restrictions apply

**Some office manufacturers offer modular electric packages but they require the installer to wire the connectors to the electrical devices in the field. Starrco’s Quick-Tric system comes from the factory with all components, including the panel board, wired with the modular connectors.

Lighting:

The standard light fixture is a 2′ x 4′ recessed fluorescent troffer designed for four 32-watt bulbs. Total watts per light fixture is 128.

Determining the modular lighting systems needed for a particular application can be a complex process involving several different formulas. Listed below are some simplified guidelines to help figure the quantity of lights needed. (Starrco standard modular lighting design is based upon 70-foot candles):

Recommended Foot Candles of Lighting

Foot Candles | 30FC | 50FC | 70FC | 100FC | 150FC |

Rooms | Lavatories | Office Area | Classroom | Drafting | Fine Drafting |

Conference Room | Stores | Proof Reading | General Assembly | Display Lighting | |

Cafeteria | Reading Room | General Assembly | Testing | Fine Assembly | |

Corridors | Rough Assembly | Inspection | Inspection | Testing | |

– | Desk Work | Testing | Counter Display | Prolonged Seeing | |

– | – | – | – | Task |

Quantity of Light @ 50FC = Square foot of room x 1.5 watts / 160 watts

Quantity of Light @ 70FC= Square foot of room x 2.0 watts / 160 watts

Quantity of Lights @ 100FC = Square foot of room x 3.0 watts / 160 watts

Note: to reduce the quantity of lights needed for an entire area, concentrate the lighting in the areas where the actual work is being performed. Limit the lighting in common or non-critical areas. This not only reduces the number of lights in an area but will also reduce cooling requirements and maintenance costs.

Outlets:

The standard design is to supply an outlet approximately every 8 linear feet of wall, unless otherwise specified. A simple design alternative is to put outlets in the areas they are needed (i.e. around workstations, equipment, etc.)

Outlets for computers, air conditioners, copiers or equipment with motors should be on separate circuits. Do not count on these outlets for general usage.

Circuit Breaker Box:

The standard circuit breaker box is a 120/240v single-phase panel capable of handling up to twelve single pole breakers. We use the following guidelines for determining the quantity of breakers supplied with each circuit breaker box:

- Twenty-eight (28) LED lights per light switch or 20-amp breaker

- Eight (8) 120v duplex receptacles per 20-amp breaker. Note: the types of modular electrical components being used may affect the quantity of receptacles assigned to each breaker. For example, if space heaters are going to be used in the office, the quantity of receptacles per breaker should be reduced because of the potential amp draw of the heaters.

- Air conditioners and HVAC units are on separate power circuits.

- Items requiring 220-250v will be on a separate two-pole breaker.

Load-Bearing In-Plant Modular Buildings

Starrco’s unique wall systems are designed utilizing wiring-studs, which carry the weight for load-bearing applications. The studs double as structural columns and vertical wiring raceways, eliminating the need for additional columns to support the structural beams for a load-bearing deck.

Depending on your unique requirements, either C-channels or I-beams are used to strengthen the 22-gauge steel B-decking. This B-decking can then carry the load for the bottom floor (to support light fixtures, air handling equipment, etc.) or for the space above it (such as an additional storage space or second-floor office).

Load-bearing designs can be used to support:

- Additional office spaces

- Record-keeping / filing rooms

- Conference and break rooms

- Equipment or material storage

- Observation platforms to oversee production floors

Stairs & Railings

Sometimes a building isn’t complete with just walls, doors, lights, and HVAC. For 2-story & load-bearing applications, stairs are provided that meet the specifications of the International Building Code and NFPA 101 Life Safety Code.

Starrguard Safety Rail is also available to protect your in-plant offices, machinery, traffic aisles, storage areas, conveyors, mezzanines, and more.

Ceiling Grid

Standard Suspended Ceiling Grid for General Applications:

Standard Suspended Ceiling Grid is a 15/16″ exposed tee system designed for use in general and fire-rated applications with maximum economy and design simplicity. Complete with Class A rated acoustical panels, the Standard Grid is perfect for your office, breakroom, or conference room.

1.5” Suspended Ceiling Grid for Heavy-Duty Applications:

1.5″ Suspended Ceiling Grid is an exposed tee system fit for heavy-duty applications to support cleanroom HEPA filters and lights. The 1.5″ grid has factory-applied closed-cell foam gaskets for controlled environments such as cleanrooms, food processing areas, and healthcare facilities.

SG-200 2” Cleanroom Ceiling Grid:

SG-200 is a 2″ structural ceiling grid designed and manufactured for a variety of cleanroom and controlled environment applications. Trusted by industry professionals for over 10 years, the system’s key components arrive fully assembled for time-saving installation.

Panelized Ceiling:

Going beyond the grid ceiling, a panelized ceiling is perfect for controlled environments. With tongue-and-groove connections for easy assembly, they can be suspended from an overhead structure or supported by structural beams below and can be designed to support maintenance load requirements. 3” panel thickness provides up to R-21 insulation value.

Wide-Rib Roof Decking:

Roof decking is an important component of most modular ceiling systems. Decking provides a base for multi-story applications & acts as a dust cover for single-story applications. It is also used to support the suspended grid ceiling. Starrco uses a Type B standard corrugated roof deck that can be interlocked or nested to extend coverage as needed. Decking is 22 gauge, 1.5” deep and prime-painted gray.

Preferred Suppliers

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.