Below-the-Hook Lifting Devices

Improve workflow efficiency and prevent employee injuries with a lifting device.

Below-the-hook lifting devices – specialized tools to help you safely and efficiently lift and move any product

A below-the-hook lifting device is a tool or mechanical device that attaches to a crane or hoist and grabs and secures a load so that it can be moved safely from one location to another. Each type is chosen based on the load’s shape, weight, material, and lifting environment. Proper use ensures safe and efficient material handling operations.

At W.W. Cannon, we understand the importance of safety and efficiency when moving loads with your crane and rigging equipment. Traditional slings like wire rope, alloy chains, or synthetic slings often aren’t enough for certain lifting applications. That’s where we come in—with custom-engineered below-the-hook lifting solutions tailored to your needs.

Below-the-Hook Lifting Devices

Why Choose a Custom Below-the-Hook Solution?

- Time Savings: Struggling to secure your load with traditional rigging methods? We can design a solution that speeds up your lifting process.

- Challenging Loads: Oversized, irregularly shaped, or heavy loads often require more than standard slings to ensure safety and stability.

- Accident Prevention: If your load feels insecure or you’ve experienced rigging failures or near-misses, it’s time to consult our experts.

- Improved Load Balance: Many loads have lifting points that aren’t ideal for safety or balance. We can create a custom device with features like adjustable bails to ensure perfect load control.

When to Consider a Custom Lifting Device

- You’re concerned about employee safety or have experienced accidents.

- The load doesn’t look or feel secure when lifted.

- You’re dealing with offset centers of gravity or unbalanced loads.

- You’re looking for a faster, more efficient, and ergonomic lifting solution for your workforce.

Protect What Matters Most

Lifting valuable or delicate materials? An improperly secured load not only puts your employees at risk but also exposes your business to costly damages. With W.W. Cannon, you’ll have peace of mind knowing your loads are safe, secure, and handled with precision.

Below-the-Hook Devices vs. End Effectors

Below-the-hook lifting devices and end effectors are used to attach loads to overhead hoisting equipment. They are used for moving any load that doesn’t have a lifting lug or a place to attach a single hoist hook to the load. They are commonly used in such applications as plate, steel, glass and drum handling, pipe lifting, stone cutting, and odd-shaped loads.

Which is right for you?

The difference between a below-the-hook lifter and an end effecter is that:

- A below-the-hook lifter normally attaches to a crane or a hoist hook.

- An end effecter is a lifting device that attaches directly to the arm of a manipulator or a manipulator control – like Gorbel’s G-Force or Easy Arm Intelligent Lifting Devices. Gorbel G-Force® and Easy Arm® Intelligent Lifting Devices are high speed, high precision, intelligent lifting devices that often require end tooling to complete a total solution that will grip, lift, move, lower and release a load and allow the full benefit of increased productivity, reduced product damage and superior ergonomics. Choosing the right end-effector tooling to complement your G-Force® and Easy Arm® is the key to maximizing your lifting solution. End-effector tooling engages the load so it can be lifted and manipulated in whatever way your application requires – whether the load needs to be flipped, turned, or rotated

No crane job is complete until you’ve got a plan for the proper rigging attachments. Many times, this can be the hardest part of the project. W.W. Cannon can help by designing a custom lifter or end effecter to pick up your specific part, so you can focus on increasing efficiency & production.

Types of Below-the-Hook Lifting Devices

Coil Lifters and Up Enders

Coil lifters and up enders help users move and maneuver coils. Use the coil hook with its pivoting wedge for small, lightweight coils. Heavy-duty C-hooks handle larger loads while slit coil C-hooks tackle multiple slit coils to maximize efficiency. Close-stacking hooks and vertical eye coil lifters help you move a wide range of coil widths and offer vertical stacking.

Drum Lifters

Used for vertical lifting and transporting of metal drums.

Fork Truck Attachments

Includes Fork Booms, Fork Beams, Fork Extensions, Battery Lifting Beams, Drum Handling

Lifting Beams

Distribute the weight of heavy or awkward loads evenly to prevent tipping or load shifts during lifting. Includes adjustable spreader/lifting beams, adjustable bail lifting beams, twin hoist rotating lifting beams, and twin hoist lifting beams. For heavy construction work, bridge work, or extreme manufacturing, utilize high-capacity lifting beams and triangle beams. Choose load leveler lifting beams and low-headroom multiple spread lifting beams for working in tight spaces.

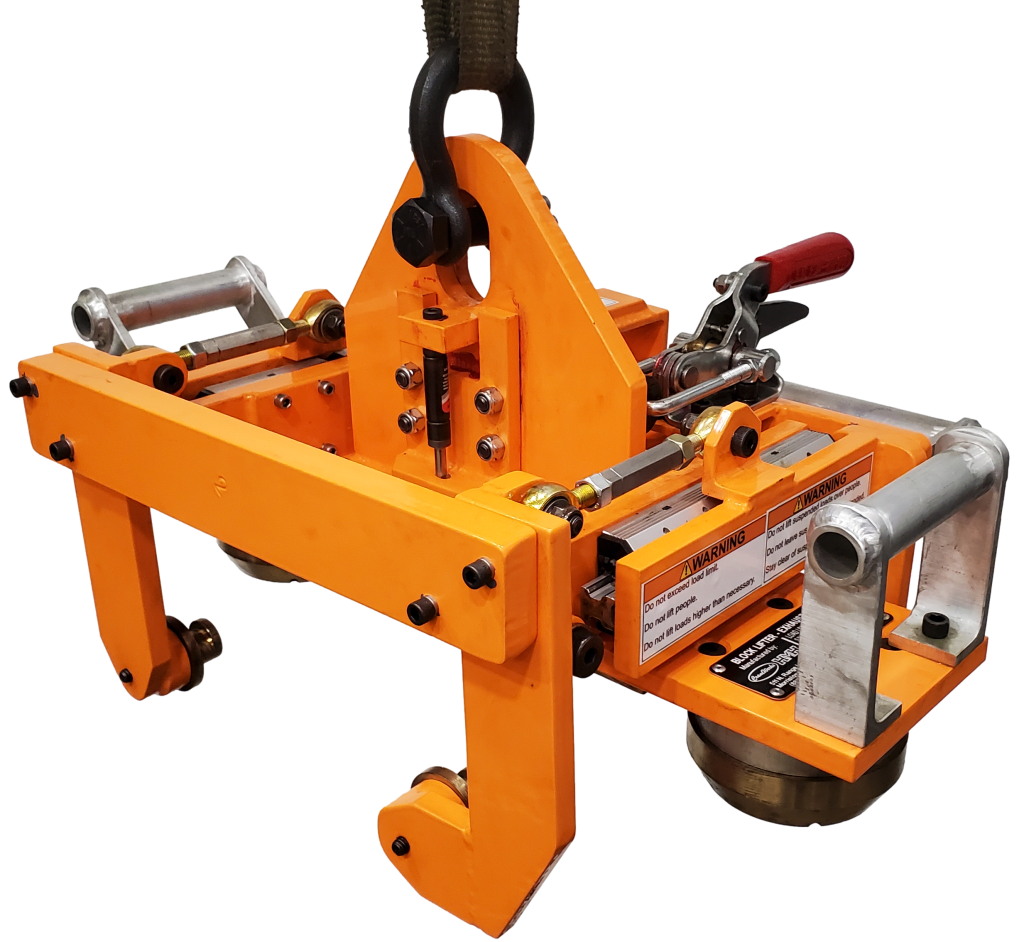

Lifting Clamps

Ideal for gripping plates, sheets, beams, pipes, or irregularly shaped objects. Lifting clamps are available in horizontal, vertical, vertical + 90°, vertical + 180°, non-marring, beam, drum, and structural shapes models. Models are also available when side loading is required. Generally used in pairs, sets of pairs, or tripod arrangement.

Lifting Points

A lifting point is the connection between the lifting means and the load. It connects the loaded goods with the lifting gear both during lifting and rotation as well as during turning and movement of loads. Lifting points are ring bolts, eyebolts, flanges etc. which the sling is attached to using hooks, shackles or other connection elements. Available in boltable, weldable, and ROV models.

Lifting Tongs

Designed to grip and lift loads securely. Excellent for lifting bales, boxes, crates, rolls, tubes, and cylindrical materials. Short loads are a good fit for single-tong styles. Longer loads require dual-gripping tongs for load stability.

Load Rotators & Positioners

A system that lifts, suspends, rotates, and positions hard-to-handle objects. Applications include fabrication and assembly, machining and metal forming, die and mold maintenance, molded product removal, material handling, storage and shipping, inspecting, cleaning, painting and repair.

Material Handling Baskets & Stands

Material handling baskets and stands help you work safer and more efficiently by raising your product to the correct height or helping you store and move product better.

Mill Duty Lifters

Robust lifting devices engineered to withstand the extreme conditions found in heavy industrial environments like steel mills, foundries, and other manufacturing facilities. These lifters are designed to move large, heavy, and often irregularly shaped loads with precision, durability, and safety. Designed to endure high temperatures, abrasive environments, and heavy usage. Available in a variety of types including lifting beams, coil lifters, slab tongs, sheet plate handling, and motorized rotating crane hooks.

Pallet Lifting

Converts your overhead crane into a lift truck for moving pallets off your dock, around your manufacturing floor, or across your warehouse. Available in adjustable forks, adjustable bail, fixed fork, hand wheel adjustable forks, and wheeled models.

Roll Lifting/Positioners

Lift and position rolls of products. Available in C-hooks, pallet lifters, roll positioners, J-hook beams, and tongs.

Rotating Crane Hooks

With full 360° rotation, the crane operator can place loads in tough-to-reach locations with ease, orienting them exactly right with a motorized rotating crane hook – in clevis and pin bail models.

Sheet Lifting

Choose small bundle sheet lifters for light-duty handling of smaller size sheets and bundles. Motorized heavy-duty sheet lifters or hydraulic sheet lifters provide versatile handling of bundles, sheets, plates, and other materials stacked horizontally. Plate Lifters offer a quick and easy solution for handling thick plates, one at a time.

Spreader Beams

Lift and move loads that are long, heavy, or awkwardly shaped with spreader beams. Keeps loads balanced by spreading the weight across multiple pick points. Fixed spreader beams and adjustable spreader beams are ideal where headroom is not limited. High-capacity spreader beams are available for your heaviest loads. The DURA-MOD modular lifting system and spreader beam end fittings allow you to customize your lifting solution to match any project.

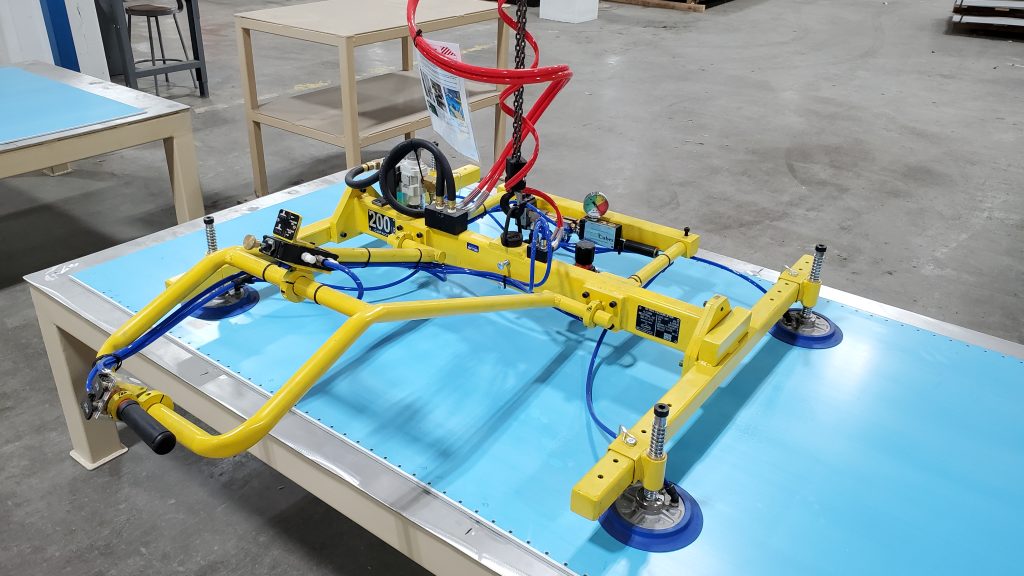

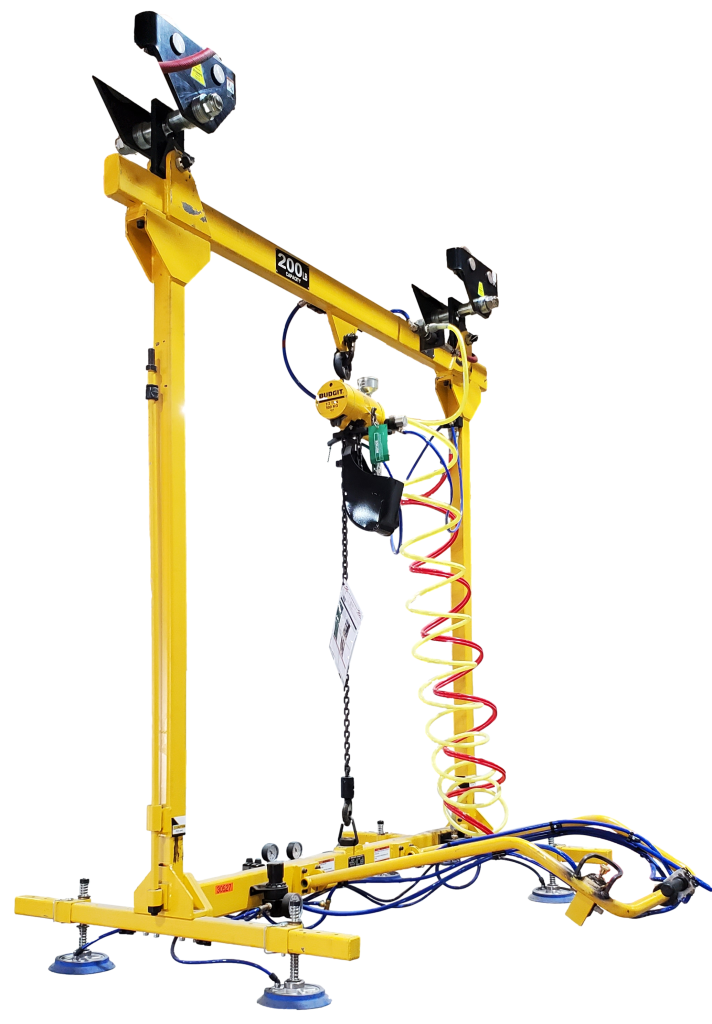

Vacuum Lifters

Use suction pads to create a strong vacuum seal on the load surface. Adjustable beams and suction cup arrangements are available to accommodate different load sizes and shapes. Designed to handle materials with smooth, non-porous surfaces, such as sheets of metal, glass, plastic, or stone. These devices eliminate the need for mechanical clamps or slings. Pneumatically or electrically powered vacuum pumps provide suction power. Various models available for narrow, nominal surface area, and wide applications, as well as 90-degree tilt upender-downender and welding hold down.

Vacuum Tube Lifters by Schmalz

Utilize a vacuum-powered tube to lift, lower, and move loads. Unlike traditional vacuum lifters, which rely on suction pads and cranes, vacuum tube lifters use a single sealed tube system to perform both lifting and gripping functions. These systems provide intuitive, one-handed operation for rapid lifting, lowering, and releasing of loads – speeding up handling tasks. Can be mounted on jib cranes, gantry cranes, or portable stands for flexibility in different work environments. Various models are available to handle loads up to 661 lbs. For handling large and flat workpieces up to 1,650 lbs. consider the VacuMaster model.

The following are considerations that go into designing customized below-the-hook lifting devices:

- How are you currently lifting?

- What are you lifting?

- What type of environment are you lifting in?

- How frequently are you lifting?

- Length and height requirements

- Low headroom or obstruction considerations

- Number of unique operations to be performed

- What are your budget constraints?

- What is your ideal timetable?

From design consultation to onsite project management and installation, W.W. Cannon can help you select the right below-the-hook lifting solution for your unique application – keeping your team safe and your operations efficient. Did we mention that we have decades of experience navigating the permitting and code compliance process? Mismanagement of these issues can lead to project delays, emphasizing the importance of our expertise in handling them effectively. We also install and service everything we sell. Check out our extensive collection of informational brochures, then contact us today and let one of our experts help you configure the right below-the-hook lifting device for your application – on time and within your budget.

Product Documents

Caldwell Roll Lifters & Positioners

Caldwell Sheet Lifters

Caldwell LIF-TRUC Forklift Attachments

Caldwell Mill Duty Lifters

Caldwell/Renfroe Lifting Clamps

Preferred Suppliers

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.