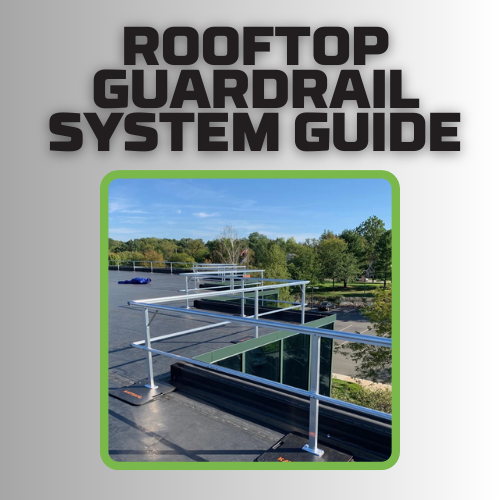

Rooftop Guardrails

OSHA-Compliant Rooftop Guardrail Systems for Fall Protection

Rooftop Guardrail Systems Provide OSHA-Compliance- Non-Penetrating & Permanent Options

Designed for permanent or temporary rooftop guardrails create a secure barrier along roof edges and access points. These low-maintenance systems protect employees and contractors during routine inspections, maintenance, and repairs, while preserving the integrity of your roof with non-penetrating and customizable mounting options.

Call us 800-442-3061

Rooftop Guardrails

Non-Penetrating Rooftop Guardrails

Watch how the GR34 freestanding guardrail system installs seamlessly—no roof penetrations required.

The GR34 non-penetrating guardrail system delivers maximum rooftop fall protection without compromising your building. Featuring a weighted base that sits on top of the roof membrane, this OSHA-compliant system is completely freestanding and ideal for membrane and built-up roofs. Sold in kit form with all required components, the GR34 is quick to install, easy to customize, and preserves the integrity of your roof.

Surface-Mounted Rooftop Guardrails

See how the GR36 guardrail mounts directly to the roof for durable, long-term solution.

Designed for challenging environments, the GR36 surface-mounted guardrail system is engineered for sloped roofs and conditions with high wind, ice, or snow loads. Anchored securely with the Kattsafe Anchor System and project-specific waterproofing, this OSHA-compliant solution ensures lasting roof protection without voiding warranties. Customizable on-site, the GR36 is trusted for demanding applications where safety and stability are non-negotiable.

W.W. Cannon provides turnkey Rooftop Guardrails—from system selection to installation and service—to keep your facility safe and compliant. View our product brochures below, then contact our safety experts for guidance.

OSHA-Compliant Rooftop Guardrails & Expert Installation

At W.W. Cannon, we specialize in the design and installation of OSHA-compliant rooftop guardrails. Our experts help you eliminate rooftop hazards, ensure OSHA compliance, and protect both your crew and your company.

Call us today for a complimentary site visit 800-442-3061

Companies Who Choose Us

Authorized Dealer & Installer

Need Additional Help?

Check Out Our Resource Hub!

.

Schedule Your Consultation with Our Experts

W.W. Cannon’s Turnkey Service Solutions result in a strong return on your investment. Get in touch with one of our specialists today for a complimentary consultation. We’ll answer any questions you have and help you plan your next steps.