Challenging Space Issues? No Problem for Modular In-Plant Office Construction

Industry: Grocery Supply Distributor in Houston TX

Challenge: Needed additional offices fast but limited on space and time.

Solution: Modular offices, Professional Installation

Result: Maintenance supervisors moved into new offices within timeline.

Equipment: Starrco Modular In-Plant Office Building

Modular Office Project | Houston, Texas

Challenge Expansion of operations requires new offices – but limited space.

Our grocery distribution client holds one of the largest privately-held wholesale grocery supply chains in the U.S.. Founded in 1918 as a supplier to independent grocery stores, they service customers of all sizes, supplying more than 7,700 independent supermarkets, chain stores, military bases and institutions with over 140,000 different products.

Extensive growth in their Houston TX location led to an expansion of their distribution operation. They needed office space for additional maintenance supervisors on the floor to monitor workers and ensure safety.

Their current facility had no options for additional office space but they did have room within their warehouse. With some creative planning, Storage Planning Specialist, Denton Brown had the answer to provide offices for their supervisors without the high cost of permanent construction.

Solution Custom In-Plant Offices Save Space and Money

“We engineered a building to the customer’s specific needs with Starrco’s help”, said Brown. “Starrco modular office designs are virtually endless for custom configurations.”

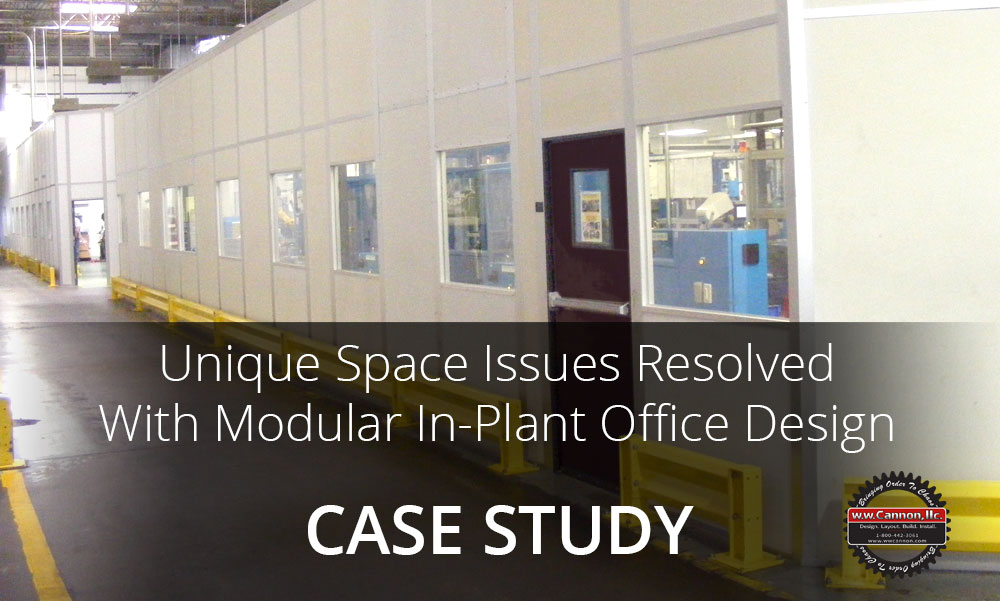

To maximize on space, the new supervisor office was built within a curve around the side of their warehouse facility. Starrco’s modular wall systems were engineered to fit within that unique spacing. The end panels on two side walls had an “L” shape cut into them to fit around a curb resulting in a perfect fit upon installation.

Result Increased Productivity, Safety and Efficiency

To keep operations running smoothly and facility maintenance crews properly supervised, it was very important that the job was done as quickly as possible to meet a tight deadline. And there was no need for permanent construction, providing our client with substantial cost savings.

“With our in-house installation crew on-site and ready to go, we were able to meet that deadline”, says Brown. Their supervisors were able to hit the ground running with new climate-controlled, professional offices.”

Next Steps

Our team of specialists knows how to turn your space challenges or production line issues into efficient results. Call us. Let’s talk through what you’re dealing with and where you’d like to see improvements. We can get you there.

Find the Right Solution

How can we help you solve your challenges? Reach out and someone will be in touch soon for more details.

Other Topics

Related Stories

Industry: Leading manufacturer of food, agriculture, industrial and animal nutrition products and services. Challenge: Provide an all-inclusive employee area customized…

WW Cannon recently completed a Vertical Reciprocating Conveyor (VRC) installation for a client in Oklahoma – providing a heavy-duty, user-friendly…

W.W. Cannon, LLC is proud to receive the reputable MHEDA MVP (Most Valuable Partner) Award again in 2024 for their…

Recently, we had the privilege of working with a client who faced a significant safety challenge: accessing HVAC units on…