Part III – Mezzanine Work Platform Decking Complete in Auto Distribution Center in CA

ResinDek flooring covers over 10,000 sf of each elevated work platform floor.

ResinDek flooring covers over 10,000 sf of each elevated work platform floor.

For this particular 20,000 sf elevated work platform being installed in an auto parts manufacturing facility in California, our client chose ResinDek Flooring to cover their mulitple platform floors. The flooring was selected due to it’s professional, polished appearance, its resilience to heavy loads, and superior wear and scratch resistance.

ResinDek floors are manufactured panels of solid composite wood construction with surface coating options that won’t separate or need heavy maintenance like other poly-deck floors. There are several surface options developed for light load accomodations, ESD protection, and heavy equipment, high traffic work areas.

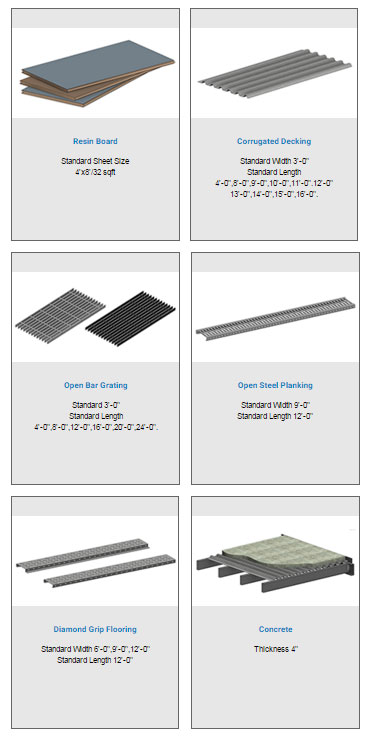

Typical Mezzanine Platform Decking Options

ResinDek – Engineered flooring panels are designed and built to withstand heavy equipment, rolling carts and pallet jack loads – up to 4500 lbs live and dead loads

10 Year Manufacturer Warranty

10 Year Manufacturer Warranty- LEED and FSC Certified

- Significant money savings over concrete

- Significant savings with ability to reduce overall amount of structural steel

- Egonomics – reduces tibial shock which reduces personnel injuries over time

- Most resilient work surface – handles rigorous demands of ultra-high rolling traffic

- Durable floor system ensures reduced maintenance over concrete and other flooring types

- Finished easy to clean surfaces

Corrugated Decking – Steel underlay of an elevated work platform. Used to reinforce resin board and concrete flooring. Galvanized top and white underside. Available in 3 different gauges.

Open Bar Grate – Ideal option when light and airflow are important. Open grate provides air circulation and lighting below your elevated platform. If used, may eliminate need for a sprinkler system.

Open Steel Plank – Ideal for wear and tear of industrial applications. Galvanized for resistance to corrosion and extra durability. Allows for light, airflow, and sprinkler penetration.

Diamond Grip Flooring – Heavy duty steel flooring option with diamond plate tread. Durable and wear-resistant. Anti-skid diamond grip provides additional traction for safety.

Concrete – Concrete over corrugated steel deck in a strong non-combustible option. Easy to clean. Permanent structure. Ideal for heavy manufacturing and wash down areas.

Other important phases of this project:

Part I – Mezzanine Footings Installation

Part II – Mezzanine Footings Complete

Or call us at 800-442-3061 for additional information on mezzanine platform systems, or any questions on your other material handling projects. We’re happy to assist you!

Or call us at 800-442-3061 for additional information on mezzanine platform systems, or any questions on your other material handling projects. We’re happy to assist you!

Find the Right Solution

How can we help you solve your challenges? Reach out and someone will be in touch soon for more details.

Other Topics

Related Stories

Industry: Leading manufacturer of food, agriculture, industrial and animal nutrition products and services. Challenge: Provide an all-inclusive employee area customized…

WW Cannon recently completed a Vertical Reciprocating Conveyor (VRC) installation for a client in Oklahoma – providing a heavy-duty, user-friendly…

W.W. Cannon, LLC is proud to receive the reputable MHEDA MVP (Most Valuable Partner) Award again in 2024 for their…

Recently, we had the privilege of working with a client who faced a significant safety challenge: accessing HVAC units on…