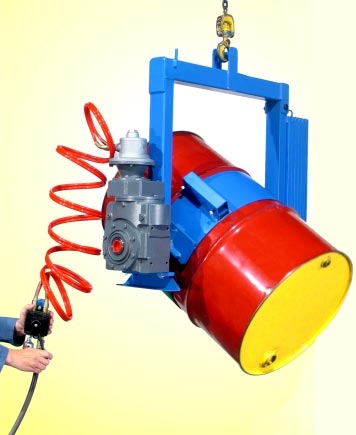

Powered Tilt Drum Handler for 360 Degree Control

Morse Powered Tilt Kontrol-Karriers

360 degree control for lifting, rotating and pouring heavy drums with your hoist or crane.

Controlled Tilting & Dispensing

Morse Drum Handling Equipment engineers designed the 195S powered drum lift to work with your hoist or crane. The below-hook lifting device offers full 360 degree rotation of suspended drums for controlled tilting and dispensing.

Capacity:

1500 Lb. (680 kg) Full drum, 800 Lb. (363 kg) Half-full drum

Features:

- Motorized drum rotation 3600 in both directions

- AC Power Tilt models have 2-button control pendant on 7 foot cord (2.1 m cord)

- Air Power Tilt models have 3 position control valve on 12 foot (3.6 m) coiled hose

- Available with single phase AC motor, 3-phase AC motor, or air motor

- Designed for 22.5″ (57 cm) diameter 55-gallon steel drum (210 liter steel drum)

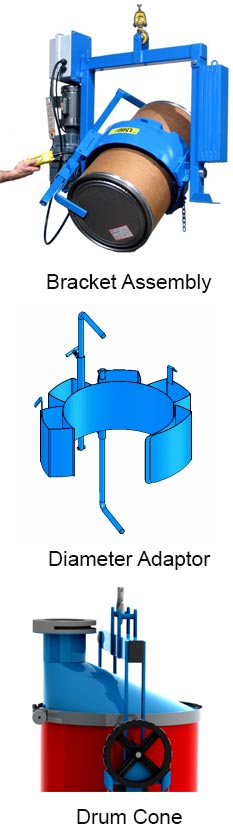

Add-Ons:

Bracket Assembly required for rimless 55-gallon (210 liter) plastic drum, and recommended to more securely hold a fiber drum, adjusts to handle a drum 31″ to 37″ (78.7 to 94 cm) tall. It can be left in place to handle any 55-gallon (210 liter) plastic, steel or fiber drum.

Diameter Adaptors for smaller diameter drums. There are Diameter Adaptors sized for a drum as small as 14″ (35.6 cm) diameter. Custom adaptors can also be made to suit your special needs.

Asymmetric Drum Cones with valve to start and stop flow of material can be used with below-hook drum carriers.

Safety:

Morse drum lifters comply with ANSI/ASME B30.20 standard for mechanical, below-the-hook lifting devices as it applies to the following:

- Rated load markings and unit identification

- Minimum design safety factor of 3, based on yield strength, for load bearing structural components

- Welding is performed by certified welders who have passed the ANSI/AWS D14.1 welding qualification test

- All welding is in accordance with ANSI/AWS D14.1 and ASME BTH-1

Or call us at 800.442.3061 for answers to your drum handling questions.

Or call us at 800.442.3061 for answers to your drum handling questions.

Find the Right Solution

How can we help you solve your challenges? Reach out and someone will be in touch soon for more details.

Other Topics

Related Stories

Industry: Leading manufacturer of food, agriculture, industrial and animal nutrition products and services. Challenge: Provide an all-inclusive employee area customized…

WW Cannon recently completed a Vertical Reciprocating Conveyor (VRC) installation for a client in Oklahoma – providing a heavy-duty, user-friendly…

W.W. Cannon, LLC is proud to receive the reputable MHEDA MVP (Most Valuable Partner) Award again in 2024 for their…

Recently, we had the privilege of working with a client who faced a significant safety challenge: accessing HVAC units on…